|

|||

|

|

|||

|

Page Title:

Finding Top Center Position for No. 1 Piston |

|

||

| ||||||||||

|

|

TM 9-2320-312-24-2

Testing and Adjusting Section

1. Remove plug (1) from flywheel housing (2). Install

i01626172

timing pin through timing hole in the flywheel

Finding Top Center Position

housing.

for No. 1 Piston

Note:

SMCS Code: 1105-531

2.

Table 4

Remove plug (3). Use the engine turning tool in

Required Tools

order to turn the engine. Do not use the eight

small bolts on the front of the crankshaft pulley.

Part Number

Description

Qty

136-4632

1

Timing Pin

Turn the flywheel in the direction of normal

engine rotation. Turn the flywheel until the timing

1

139-7064

Timing Pin Adapter

pin engages with the hole in the flywheel.

1

9S-9082

Engine Turning Tool

Note: If the flywheel is turned beyond the point of

engagement, the flywheel must be turned in the

direction that is opposite of normal engine rotation.

Turn the flywheel by approximately 30 degrees.

Then turn the flywheel in the direction of normal

engine rotation until the timing pin engages with

the threaded hole. When the No. 1 piston is at the

top center position, this procedure will remove the

play from the gears.

3. Remove the valve cover.

The inlet valves and the exhaust valve for the No.

1 cylinder are fully closed under two conditions:

g00842050

Illustration 45

No. 1 piston is on the compression stroke.

Timing Hole Location (Typical Example)

The rocker arms can be moved by hand.

If the rocker arms cannot be moved and the

valves are slightly open, the No. 1 piston is on

the exhaust stroke.

Note: Refer to Testing And Adjusting, "Crankshaft

Positions for Valve Lash Setting".

4. After the timing bolt has been installed in

the flywheel, complete these procedures, as

required:

a. Find the cylinders that need to be checked

for the stroke position of the crankshaft.

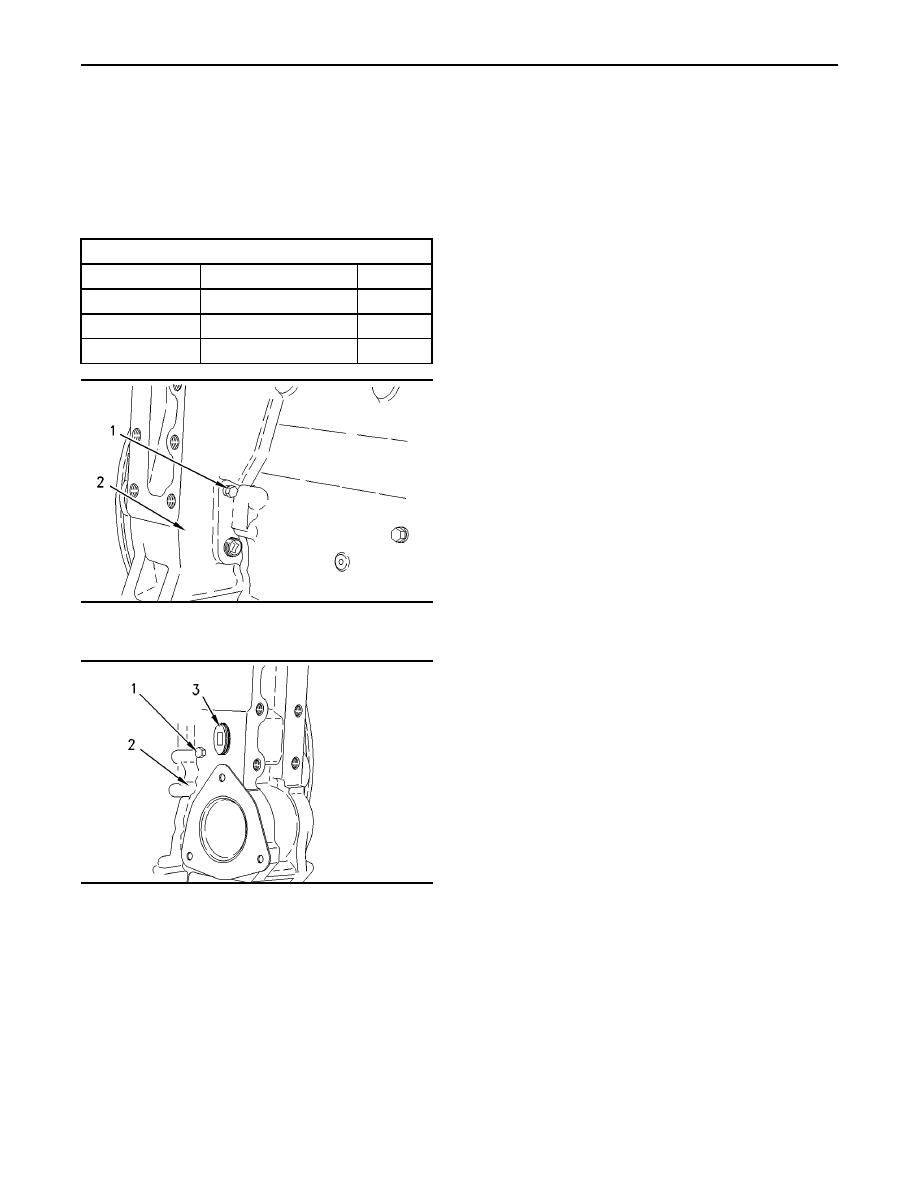

g00842034

Illustration 46

b. Find the cylinders that need to be adjusted

Timing Hole Location (Typical Example)

for the stroke position of the crankshaft.

Note: The hole for the timing pin can be in one of

5. When the actual stroke position is identified and

two positions:

the other stroke position is needed, remove the

timing bolt from the flywheel.

The right front face of the flywheel housing

(Illustration 45)

6. Turn the flywheel by 360 degrees in the direction

of normal engine rotation.

The left front face of the flywheel housing

(Illustration 46)

Note: The timing hole is used during the procedure

to set the valve lash.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |