|

|||

|

|

|||

|

Page Title:

Valve Operation for RUNNING ENGINE |

|

||

| ||||||||||

|

|

28

TM 9-2320-312-24-2

Systems Operation Section

Valve Operation for RUNNING ENGINE

g00295338

Illustration 14

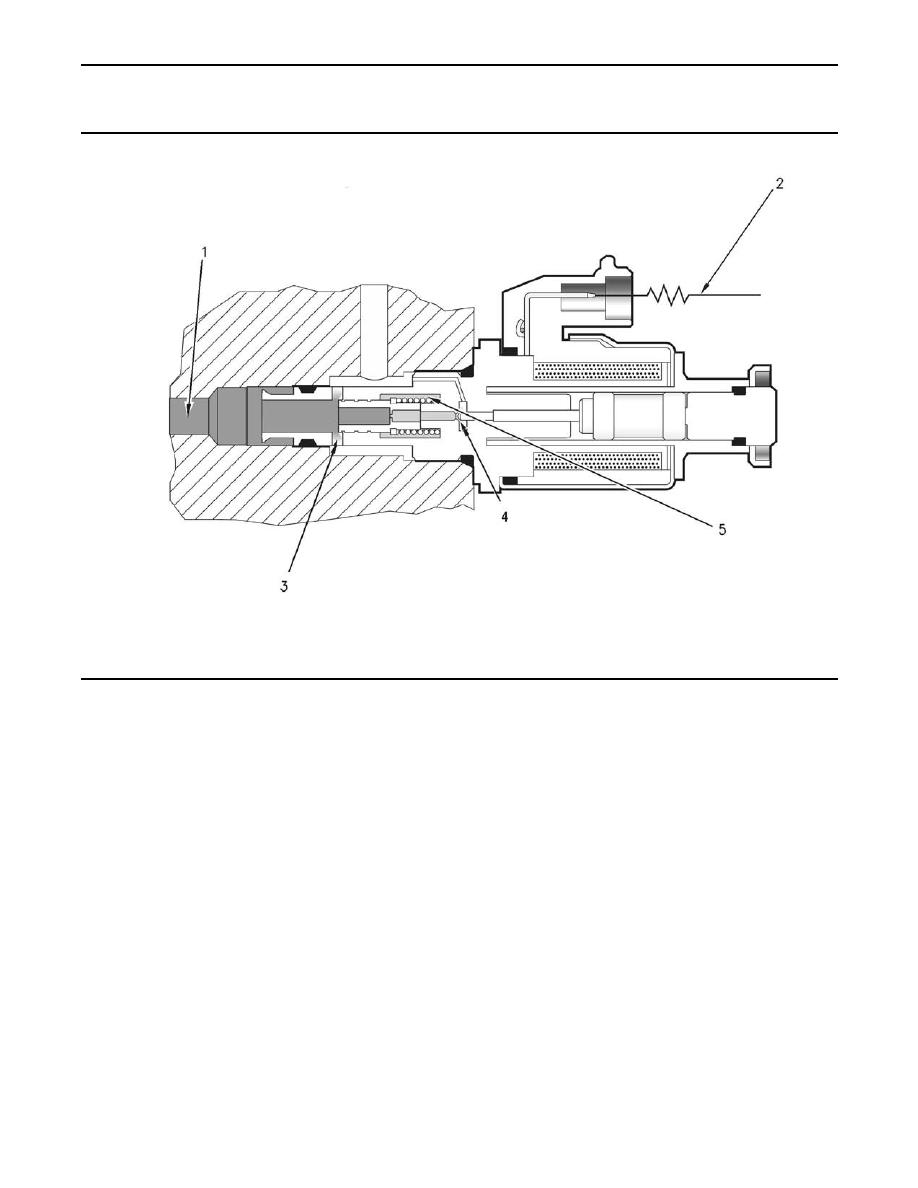

Operation of the injection actuation pressure control valve (running engine)

(1) Pump outlet pressure

(3) Drain port (open)

(5) Reduced pressure oil

(2) Current from the ECM

(4) Poppet (open)

The magnetic force that is applied to the poppet

Once the engine starts, the ECM controls the

holds the poppet closed. When the poppet is

current (2) to the IAP Control Valve in order to

closed, the pressure in the spool spring chamber

maintain the desired actuation pressure. The IAP

increases. When the pressure in the spool spring

Sensor monitors the actual actuation pressure in

chamber exceeds the magnetic force that is holding

the high pressure oil passage in the cylinder head.

the poppet closed, the poppet (4) will move to the

The ECM compares the actual actuation pressure

right. When the poppet (4) moves to the right, some

to the desired actuation pressure 67 times per

of the pressure oil in the spool spring chamber

second. When these pressures do not match, the

escapes to the drain. This causes the pressure in

ECM adjusts the current levels (2) to the IAP Control

the spring chamber to drop. When the pressure

Valve in order to make the actual injection actuation

in the spring chamber drops, the poppet closes.

pressure equal to the desired injection actuation

When the poppet closes, the pressure again begins

pressure.

to increase and the cycle is repeated. This process

controls the reduced pressure oil (5) in the spool

The amount of current that is sent to the solenoid

spring cavity. The reduced pressure oil (5) in the

regulates the amount of magnetic force that is

spool spring cavity acts on the spool. The reduced

trying to hold the poppet closed. The solenoid,

pressure oil (5) in the spool spring cavity tries to

the armature and the push pin simulate a variable

move the spool to the left. When the spool is moved

spring that is electronically controlled. Increased

to the left, the drain port (3) is blocked.

current results in increased force. Decreased

current results in decreased force.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |