|

|||

|

|

|||

|

Page Title:

GENERAL INFORMATION - CONTINUED |

|

||

| ||||||||||

|

|

TM 9-2320-303-24-2

AIR CONDITIONER COMPRESSOR SERVICE - CONTINUED

0301 00

GENERAL INFORMATION - CONTINUED

2.

Air conditioning system should have approximately 14 fl oz (414 ml) of refrigerant oil. There should be 10 fl oz (296

ml) in compressor.

3.

Each major component has approximately 2 fl oz (59 ml) of refrigerant oil. Therefore, additional oil must be added to

compressor when a major component is replaced.

EXAMPLE:

If condenser and receiver-dryer are to be replaced, first check oil level in compressor. Compressor should have 10 fl oz

(296 ml). Add oil if needed. Then, after replacing condenser and receiver-dryer, add an additional 4 fl oz (118 ml) of oil

to compressor. Entire system should then have approximately 14 fl oz (414 ml).

SERVICE

WARNING

DO NOT remove air conditioner compressor oil fill plug without first recovering refrigerant from sys-

tem. Failure to recover system could cause uncontrolled release of high pressure refrigerant, which can

freeze skin and eye tissue causing serious injury or blindness.

Use care to prevent refrigerant from touching your skin or eyes. Liquid refrigerant, when exposed to air,

quickly evaporates and will freeze skin or eye tissue. Serious injury or blindness may result if you come

in contact with liquid refrigerant.

1.

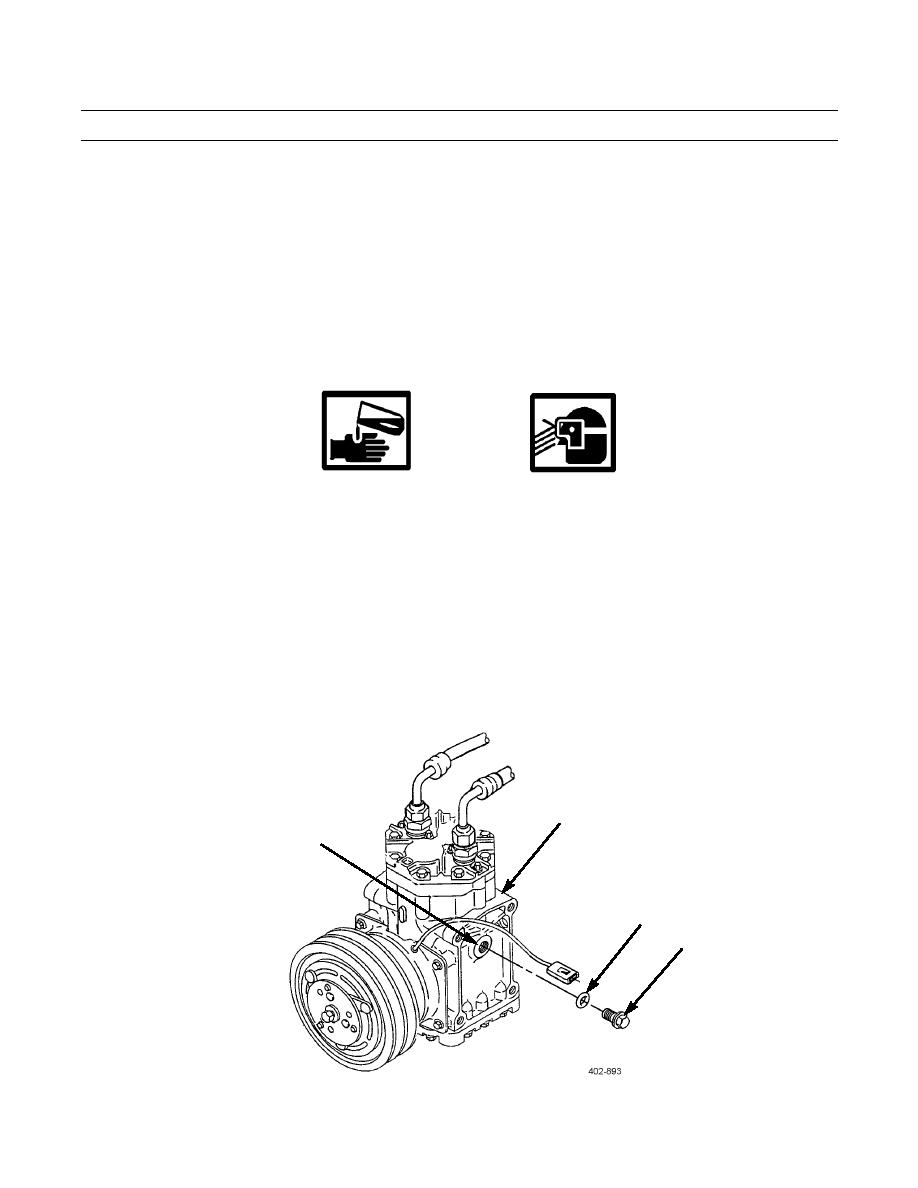

Remove oil fill plug (3) and preformed packing (2) from compressor (1). Retain preformed packing if not damaged or if

there are no signs of leaks.

2.

Use oil level gage to check oil level in compressor (1).

a.

If gage bottoms out before going in more than 3 in (7.6 cm), it is hitting compressor crankshaft. Rotate drive plate

by hand and insert gage until it contacts bottom of sump.

1

1,2

2

3

0301 00-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |