|

|||

|

|

|||

|

Page Title:

Table 5. Calculating Correct Solid Rivet Length. |

|

||

| ||||||||||

|

|

TM 9-2320-303-24-2

CAB BODY REPAIR - CONTINUED

0289 00

RIVET REPLACEMENT - CONTINUED

Table 5. Calculating Correct Solid Rivet Length.

Rivet Diameter

Material Thickness

Add

1/4 in or less

2 in or less

1-1/2 x diameter of rivet

1/4 in or less

over 2 in

1-1/2 x diameter of rivet + 1/16 in for

every 2 in of material thickness

5/16 in or more

1 in or less

1-1/2 x diameter of rivet

5/16 in or more

over 1 in

1-1/2 x diameter of rivet + 1/16 in for

every 1 in of material thickness

7.

Rivet Driving Practices and Precautions. Riveting is the major means of joining body parts. Proper procedures must

be followed to maintain high-quality workmanship. Table 6 lists types of faulty rivet installations, causes, and corrective

action to be taken.

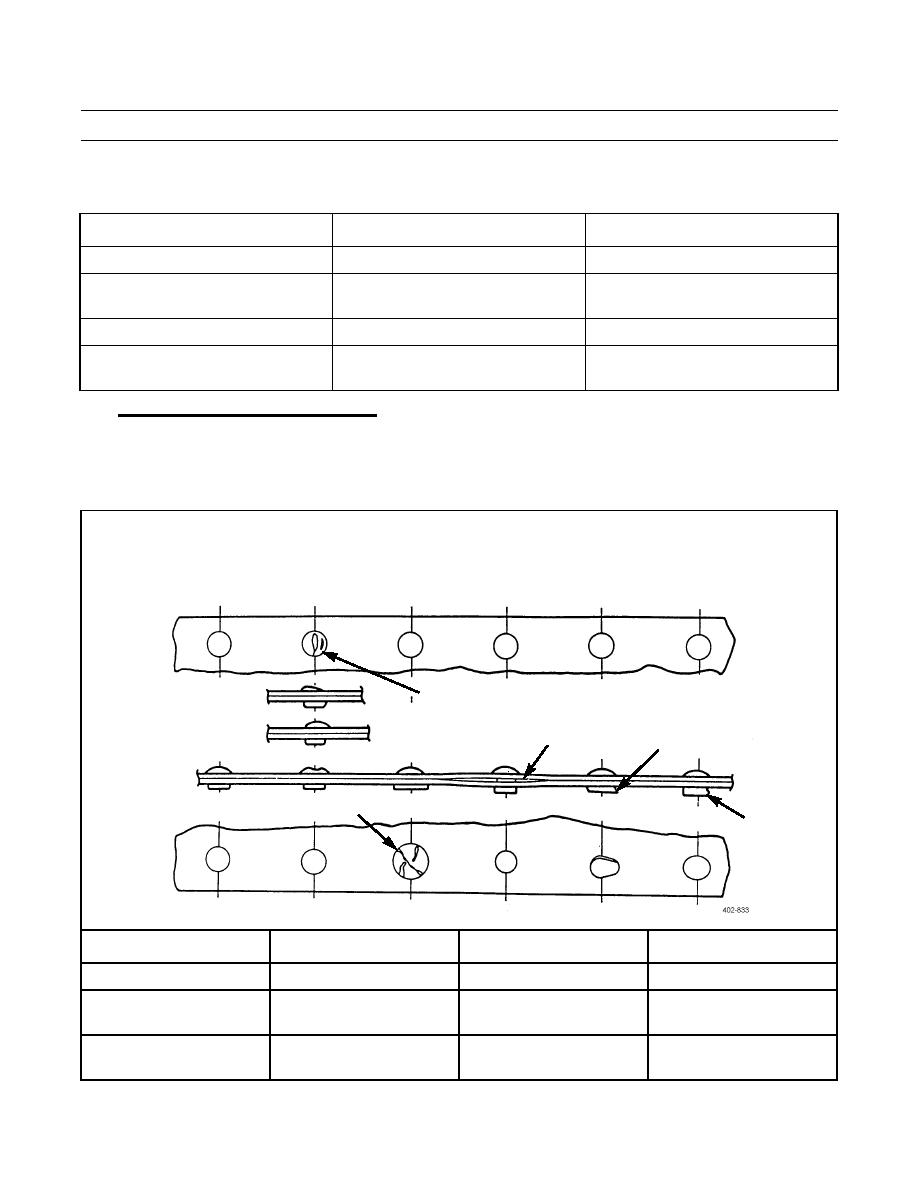

Table 6. Correctly and Incorrectly Driven Rivet.

TOP VIEW

(F)

(A)

(E)

(D)

(C)

(B)

DRIVEN

DRIVEN

SEPARATION UNSTEADY

EXCESSIVE

UNSTEADY

EXCESSIVELY OF SHEETS RIVET SET SHANK LENGTH

CORRECTLY

TOOL

DAMAGED HEAD

SWELLED

SLOPING

SHANK

HEAD

CRACKS

BUCKLED

SHANK

BOTTOM VIEW

Imperfection

Cause

Remedy

Action

None

None

None

None

Cut head

Improperly held tools.

Hold riveting tools firmly Replace rivet.

against work.

Excessive flat head, resultant Excessive driving, too much Improve riveting technique.

Replace rivet.

head cracks

pressure on bucking bar.

0289 00-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |