|

|||

|

|

|||

|

Page Title:

Assemble the Main Differential and Ring Gear Assembly |

|

||

| ||||||||||

|

|

TM 9-2320-303-24-2

FORWARD-REAR AXLE DIFFERENTIAL CARRIER REPAIR - CONTINUED

0257 00

DIFFERENTIAL CARRIER ASSEMBLY - CONTINUED

b.

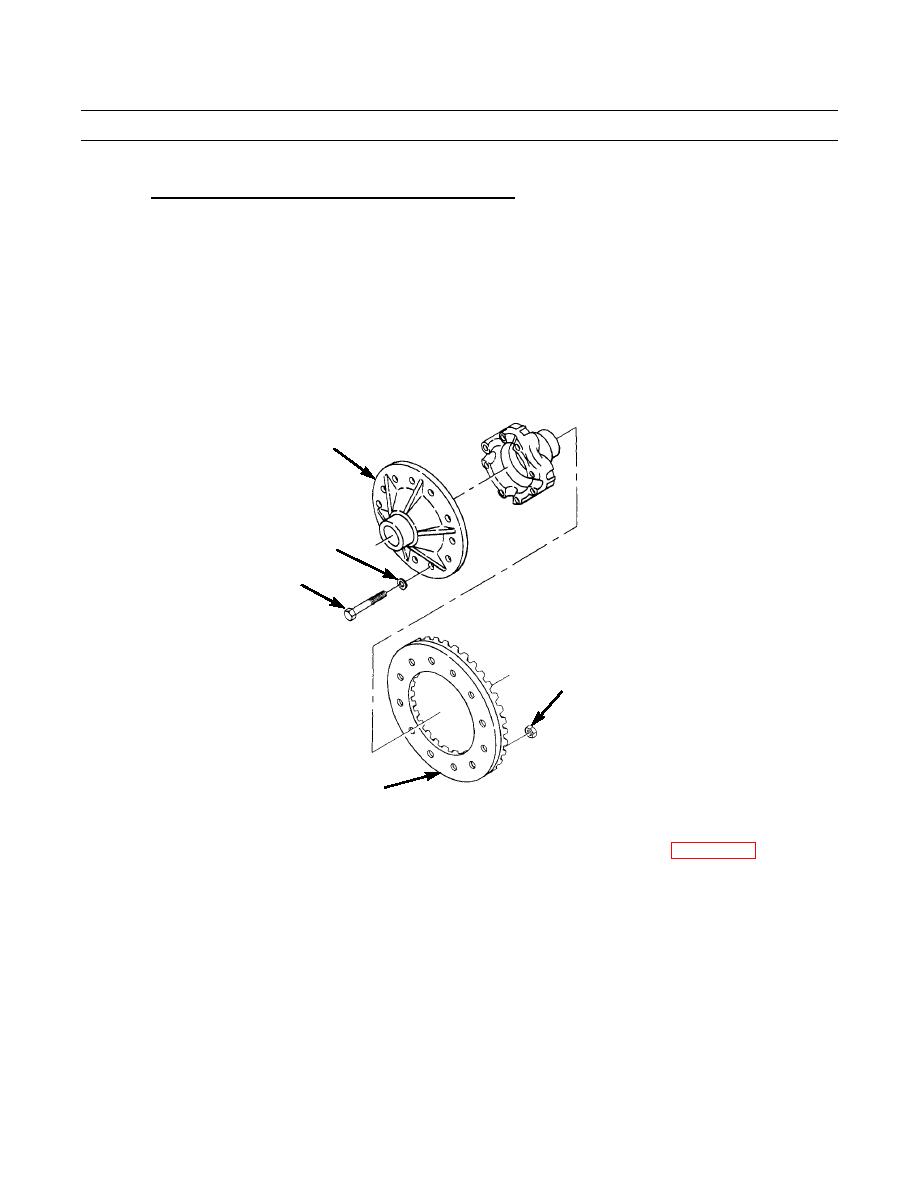

Assemble the Main Differential and Ring Gear Assembly.

CAUTION

The ring gear should not be pressed or driven on the case, as this would cause excessive metal particles to

lodge between the gear and the case, thus resulting in gear run-out. Proper installation should, therefore,

incorporate preheating the gear to assure correct interference fit and to eliminate metal pick up.

(1)

Heat the ring gear (77) in oil to approximately 1600F-1800F (71.1C-82.2C) for about ten minutes

before assembly.

(2)

If ring gear (77) has been separated from case (76), fasten with 12 bolts (80), washers (81), and nuts (82).

Torque to 180-230 lb-ft (244-312 Nm).

76

81

80

82

77

402-979

(3)

Assemble and install spider (88) assembly as follows.

(a) Lightly lubricate all parts with recommended gear case lubricant (Item 33, WP 0312 00).

(b) Lay ring gear and large half of case on bench with the bearing end of case (76) hub down and the inner

case facing upward. Be sure no thrust washers are inside the case.

0257 00-26

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |