|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-302-20-2

FRONT HUB, DRUM, WHEEL BEARINGS, AND SEAL REPLACEMENT (M915A3) - CONTINUED

0207 00

INSTALLATION

WARNING

Brakeshoe linings and inside drum friction surface must be free of all oil/grease and other contaminants

prior to assembly to ensure maximum braking capability. Oil/grease and other contaminants may compro-

mise braking that could lead to a serious accident resulting in injury and/or death.

NOTE

Perform step 1 if new bearing races or new bearings are being installed.

1.

Install outer bearing race (4) and inner bearing race (7) in bore of hub (5).

NOTE

Ensure ABS tone ring seat on hub is clean and seat is not damaged. If seat is damaged, replace hub.

2.

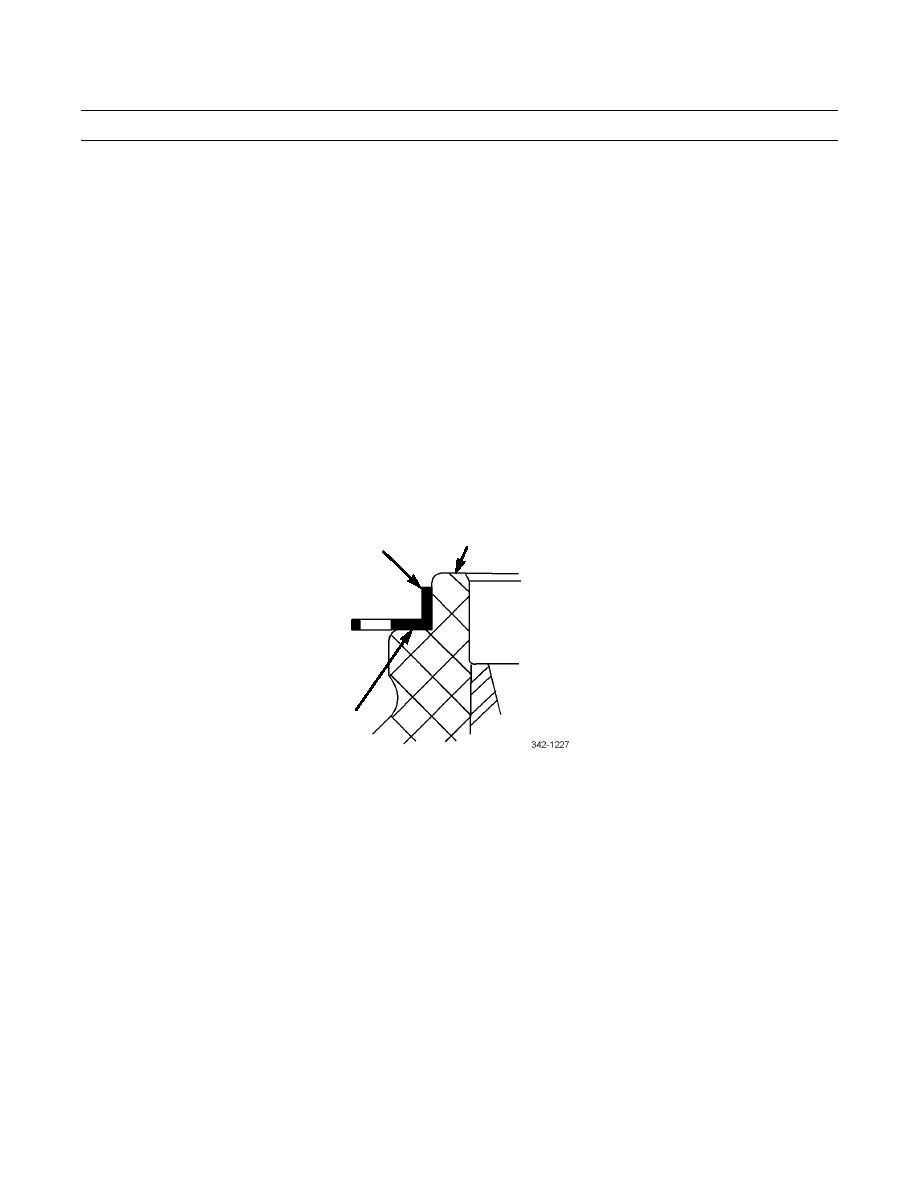

If removed, install ABS tone ring (6) on hub (5) as follows:

a. Place ABS tone ring (6) on hub ring seat (22) with inside diameter flange of ring up.

b. Center installation tool over ABS tone ring (6).

c. Using driver handle and hammer or mallet, drive ABS tone ring (6) onto hub ring seat (22). Inspect ring to ensure

complete seating on hub (5).

5

6

22

3.

Coat two wheel bearings (8 and 12) with clean gear lubricating oil.

4.

Install inner wheel bearing (12) and new oil seal (9) in hub (5).

5.

Apply coat of gear lubricating oil to axle spindle (10).

CAUTION

To prevent damage to equipment, do not unseat oil seal or wheel bearing when mounting hub.

6.

Mount hub (5) fully over axle spindle (10).

7.

Fill cavity in hub (5) with gear lubricating oil.

8.

Install outer wheel bearing (8) in hub (5).

NOTE

Install adjusting nut with dimple facing out.

9.

While turning hub (5), thread adjusting nut (21) on axle spindle (10) until against outer wheel bearing (12).

10.

While turning hub (5) in both directions, tighten adjusting nut (21) to 100 lb-ft (136 Nm).

11.

Loosen adjusting nut (21) completely to zero torque and spin wheel a few turns. Tighten adjusting nut to 50 lb-ft (68

Nm).

12.

Back off adjusting nut (21) 1/6 to 1/4 turn.

0207 00-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |