|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-302-20-2

DRIVELINE MAINTENANCE (M915A3 NEW MODEL, M916A3, M917A2) - CONTINUED

0166 00

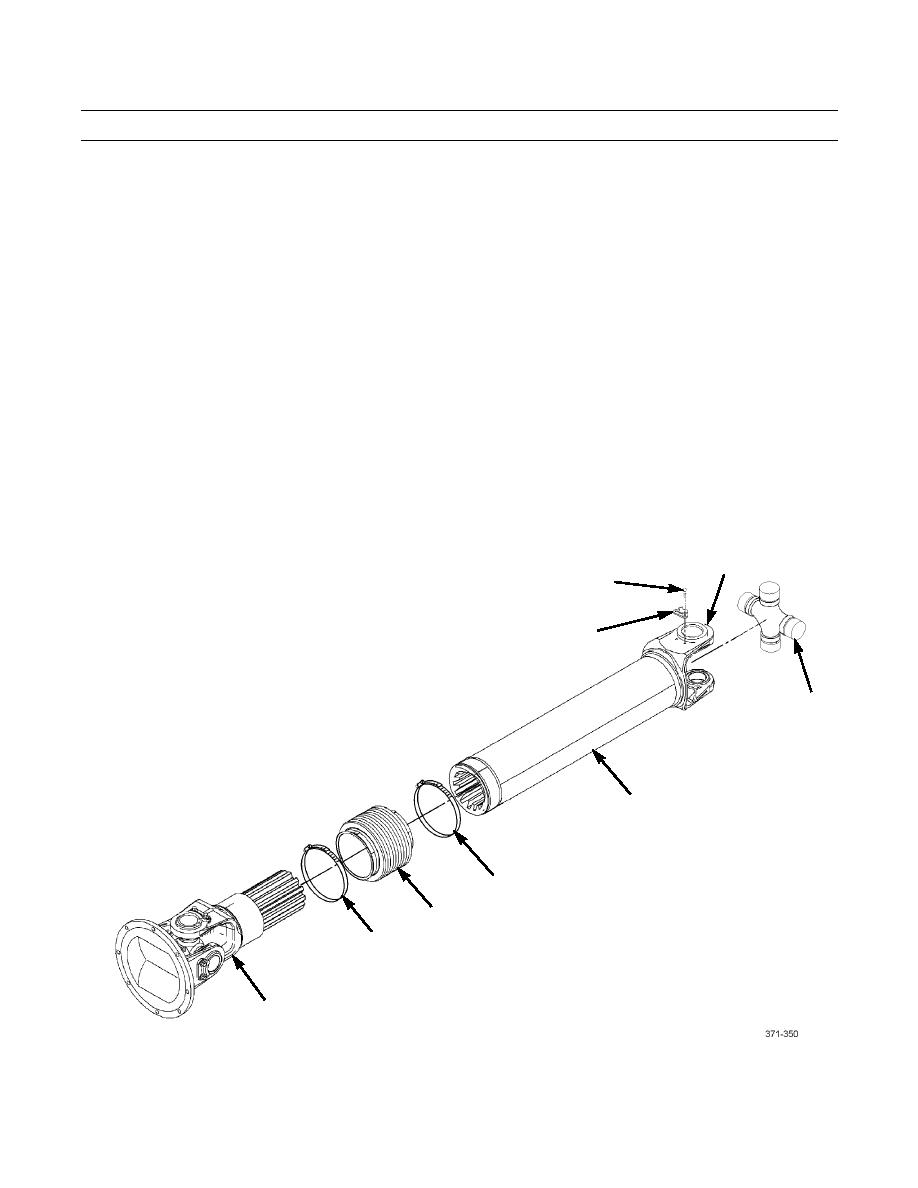

DRIVELINE REPAIR

NOTE

Perform steps 1 through 4 to replace bearing and steps 5 through 11 to replace bellows.

1.

Remove four screws (10) and two retainers (9) from yoke (11).

2.

Remove bearing (12) from yoke (11).

3.

Install bearing (12) into yoke (11).

4.

Install two retainers (9) and four screws (10) on yoke (11). Tighten screws to 100-120 lb-ft (135-160 Nm).

5.

Make matchmarks at each end of driveline and adjoining components to aid in installation.

6.

Loosen clamp (14) at each end of bellows (15).

7.

Remove yoke (16) from tube (13).

8.

Remove bellows (15) from tube (13).

9.

Place clamp (14) on each end of bellows (15) and slide bellows onto tube (13).

10.

Position yoke (16) through bellows (15) and into tube (13) in accordance with matchmarks made during removal.

11.

Tighten clamp (14) at each end of bellows (15).

11

10

9

12

13

14

15

14

16

END OF WORK PACKAGE

0166 00-3/(-4 Blank)

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |