|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-302-20-2

ELECTRICAL CONNECTORS MAINTENANCE - CONTINUED

0151 00

SPLICING - CONTINUED

d.

Insert one wire into splice clip (P/N: 0597428 or equivalent) and crimp.

e.

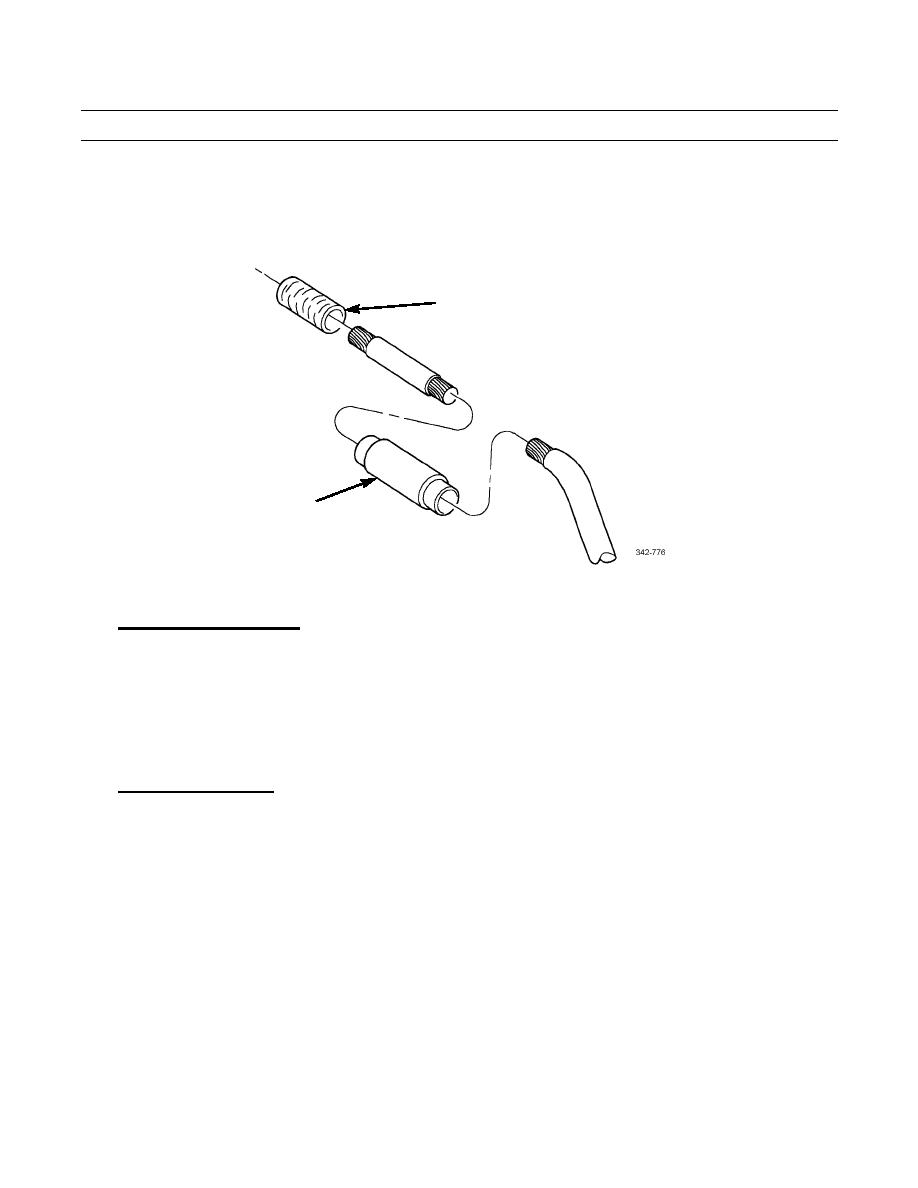

Insert other wire into splice and crimp (Figure 19).

SHRINK WRAP

SPLICE CLIP

Figure 19. Spliced Wire.

Soldering Splice Connectors. See TB SIG 222 for more information about solder and soldering. Soldering splice con-

3.

nectors is optional. To solder splice connectors:

a.

You MUST use rosin core solder.

b.

Check exposed wire before splice is crimped in connector. Exposed wire MUST be clean before splice is crimped.

c.

Use a suitable electronic soldering iron to heat wires. Apply solder to heated wire (not to soldering iron) allowing

sufficient solder flow into splice joint.

d.

Pull on connection to ensure crimping and soldering integrity.

Heat Shrinkable Tubing.

4.

a.

Shrink wrap is required. Alpha FIT-300, Raychem TAT-125 or any equivalent heat shrink dual wall epoxy encap-

sulating adhesive polyolefin is required. The following are sources of supply:

Alpha Wire Corp

711 Lidgerwood Ave

P.O. Box 711

Elizabeth, New Jersey 07207-0711

1-800-5 2ALPHA

Raychem Corporation, Thermofit Div

300 Constitution Drive, Bldg. B

Menlo Park, CA 94025

415-361-3860

0151 00-21

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |