|

|||

|

|

|||

|

Page Title:

PREPARTION FOR SHIPMENT AND STORAGE |

|

||

| ||||||||||

|

|

TM 55-1740-200-14

a. Locate the tractor so there is sufficient room on all

b. Check hydraulic reservoir (8) for proper fluid level.

sides to perform inspections and maintenance while it is

Add oil (item 5, table 1-3) as required. Use hydraulic

in storage. Jack up the tractor and lift tires off the

fluid (item 6, table 13) if temperatures range from 0F

surface and place suitable blocks under the frame.

(-18C) to -65F (-54C).

b. Perform a monthly inspection while the equipment

c. Check the transfer case (4) for proper oil level. Add

is in storage and inspect for evidence of physical damage,

oil (item 7, table 1-3) as required.

such as rusting, accumulation of water, pilferage, or

leakage.

d. Verify proper oil level in front and rear axle

differentials. Add oil (item 8, table 1-3) as required. Use

3-16. SHIPMENT. The towing tractor is designed to

lubricating oil (item 9, table 1-3) if temperatures range

operate in a temperature range of -20F to 125F

from 0F (-18C) to -65F (-54C).

without winterization kit. If shipment will subject the

towing tractor to temperatures in excess of this range, a

e. Start engine and check engine oil pressure gage for

winterization kit shall be installed.

pressure of 40 pounds or more.

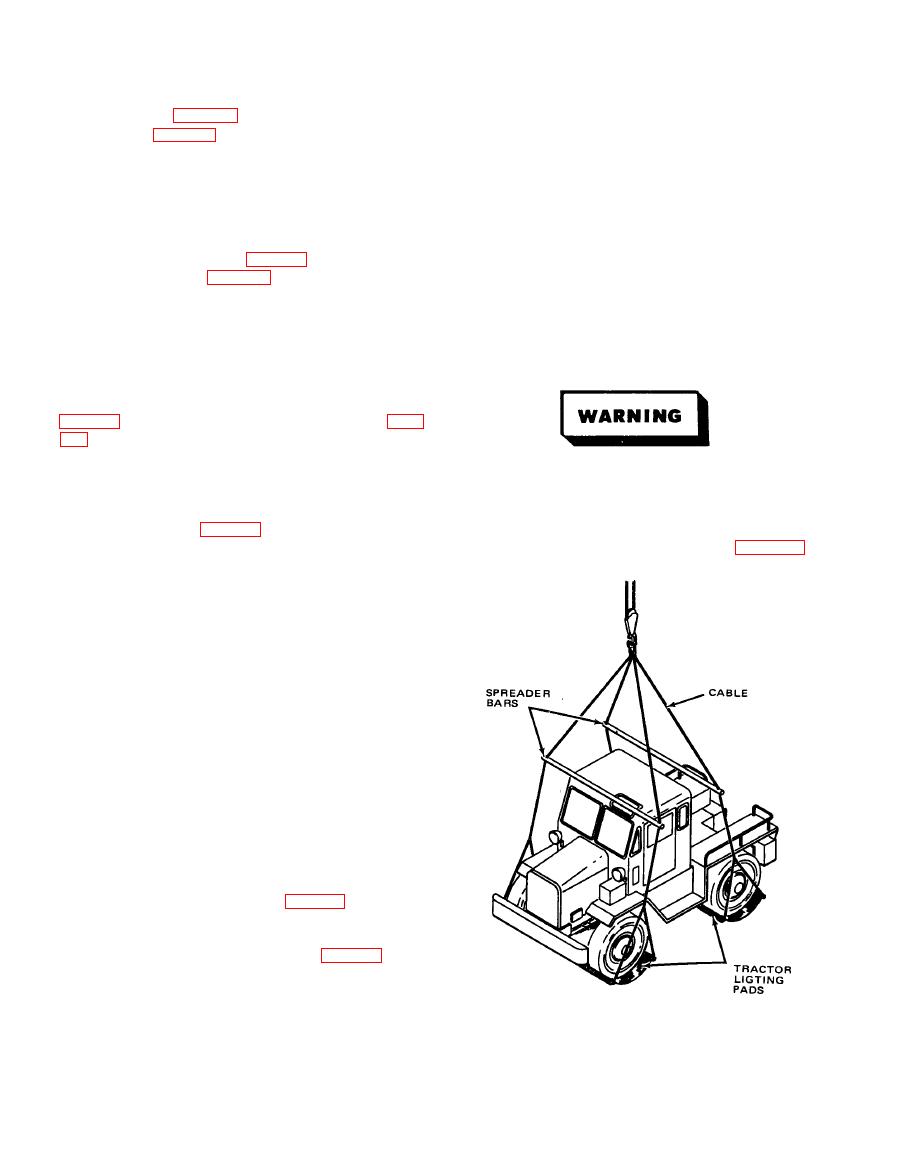

3-1 7. LIFTING THE TOWING TRACTOR.

f. Check hydraulic transrnission dipstick (5) for proper

oil level while the engine is running. Add oil (item 5,

(-54C).

Tractor weight is 5.5 tons. Proper capacity

crane should be used.

g. After normal operating temperature (160F) has

been reached, stop the engine and recheck engine oil

3-18. The tractor is not equipped with lifting eyes for

level. Add oil (item 3, table 1-3) as required.

crane and cable lifting. During tractor lifting by crane use

spreader bars to prevent tractor damage. (See figure 3-1.)

FOR

SHIPMENT

AND

312. PREPARATION

STORAGE.

3-13. Before shipment or storage, the towing tractor

shall be given a thorough operational inspection and

prepared as follows:

a. Remove the drain plug from the fuel tanks and

drain the fuel into a suitable container.

b. Drain the carburetor and fuel lines into a suitable

container.

c. Disconnect the battery cables from the battery.

d . Drain the hydraulic system and refill with

p r e s e r v a t i v e hydraulic oil.

e . Drain the hydraulic pump and refill with

preservative hydraulic oil, (item 10, table 1-3).

f . Drain the engine crankcase and refill with

corrosion-preventive compound, (item 11, table 1-3).

g. Cap all inlet and outlet parts.

3-14. LIMITED STORAGE AND SHIPMENT.

AV 008859

3-15. The following criteria shall be adhered to when

the towing tractor is placed in limited storage.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |