|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2420-224-34

CRANE

HYDRAULIC

MOTOR

REPAIR

(CONT)

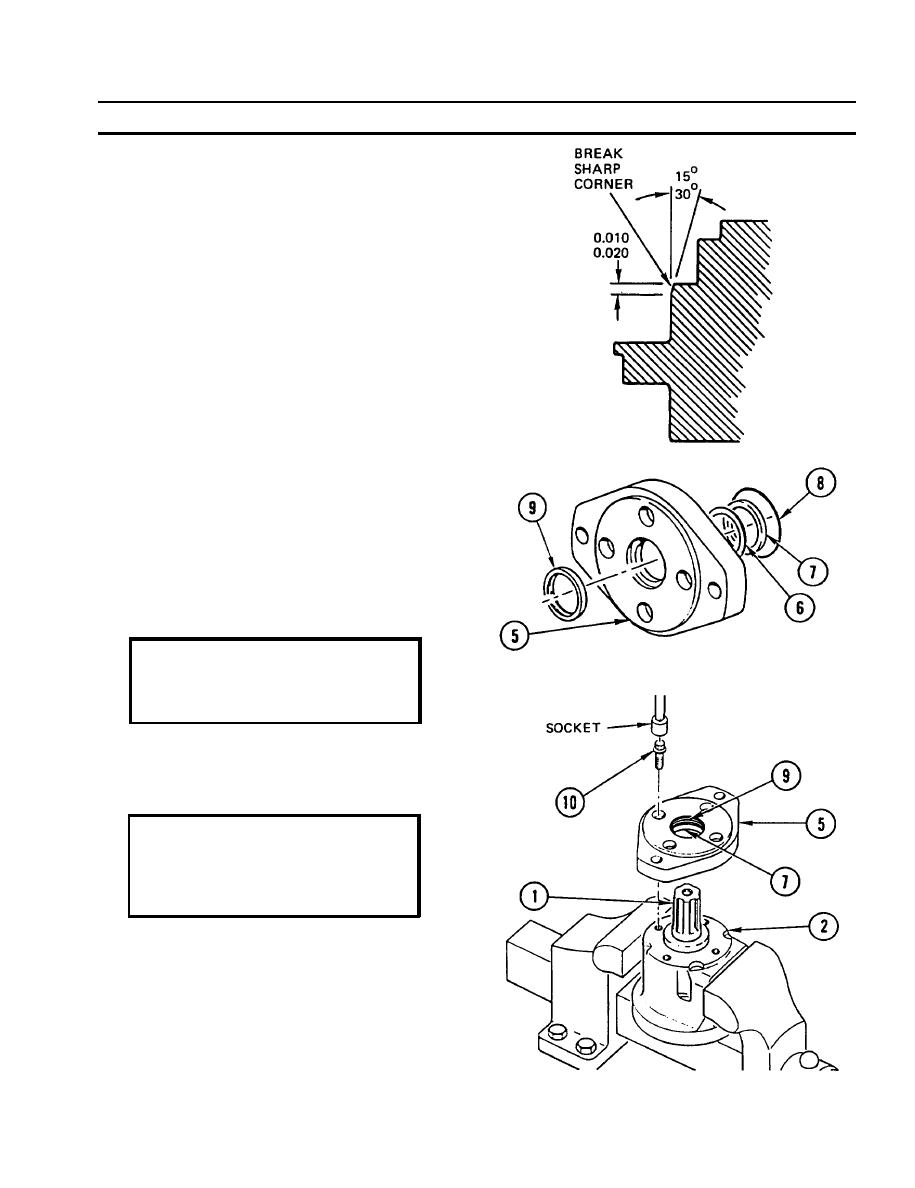

4.

IF INSTALLING new mounting FLANGE (5),

BREAK seal seat CORNER with emery cloth.

5. INSTALL retaining ring (6), new SEAL (7),

and new seal (8) in mounting flange (5).

INSTALL new SEAL (9) in mounting flange

6.

(5).

7.

A P P L Y three or four drops of SEALING

COMPOUND to threads of manifold HOUSING

(2).

APPLY COAT of LUBRICATING OIL to output

8.

SHAFT (1), SEAL (7), and SEAL (9).

CAUTION

Make sure seals are

not

i n v e r t e d or damaged.

INSTALL mounting FLANGE (5), ROTATING

9.

SLOWLY while pushing down over output

shaft (1).

CAUTION

Do not overtighten vise jaws.

E x c e s s i v e clamping force may

d i s t o r t housing.

10.

PLACE crane hydraulic MOTOR in soft-jawed

vise by CLAMPING across PORTS.

11.

USING SOCKET, INSTALL four SCREWS

(10) and ALTERNATELY TIGHTEN to

250 lb-in. (28 N.m).

20-247

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |