|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2420-224-34

CYLINDER BLOCK REPAIR (CONT)

NOTE

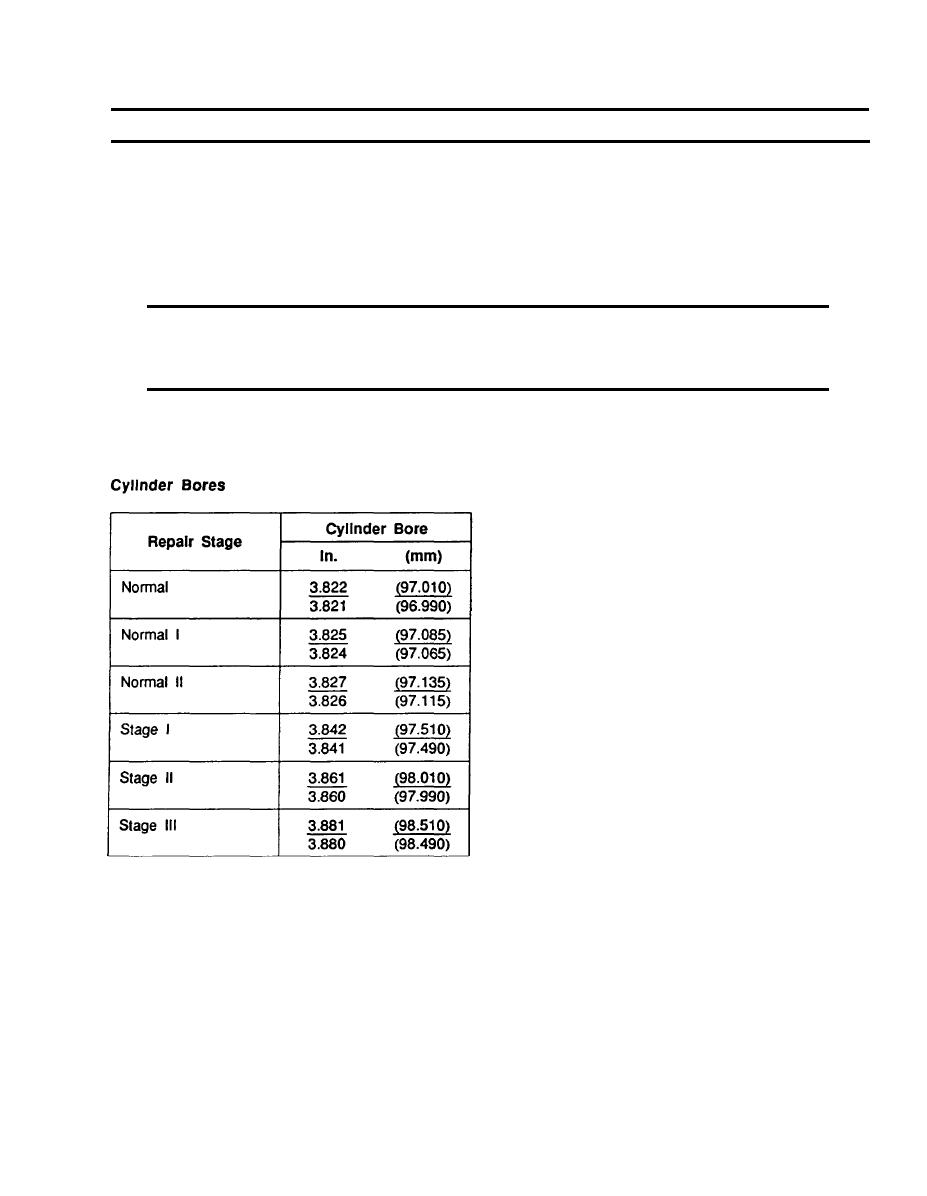

If inspection shows that cylinder boring is required, bore all six cylinders to next repair

stage.

3. Secure crankcase on drill press.

4.

Aline cylinder to be bored with drill. Center drill above return point of first piston ring at TDC.

CAUTION

B o r e crankcase cylinders in following order: 1-3-5-2-4-6. Failure to do so could

c a u s e thermal stress on cylinder walls.

5.

Clamp boring tool onto drill. Using the two following tables, bore cylinder to within 0.002 in. (0.05 mm)

of final diameter.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |