|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2420-224-34

CYLINDER BLOCK REPAIR (CONT)

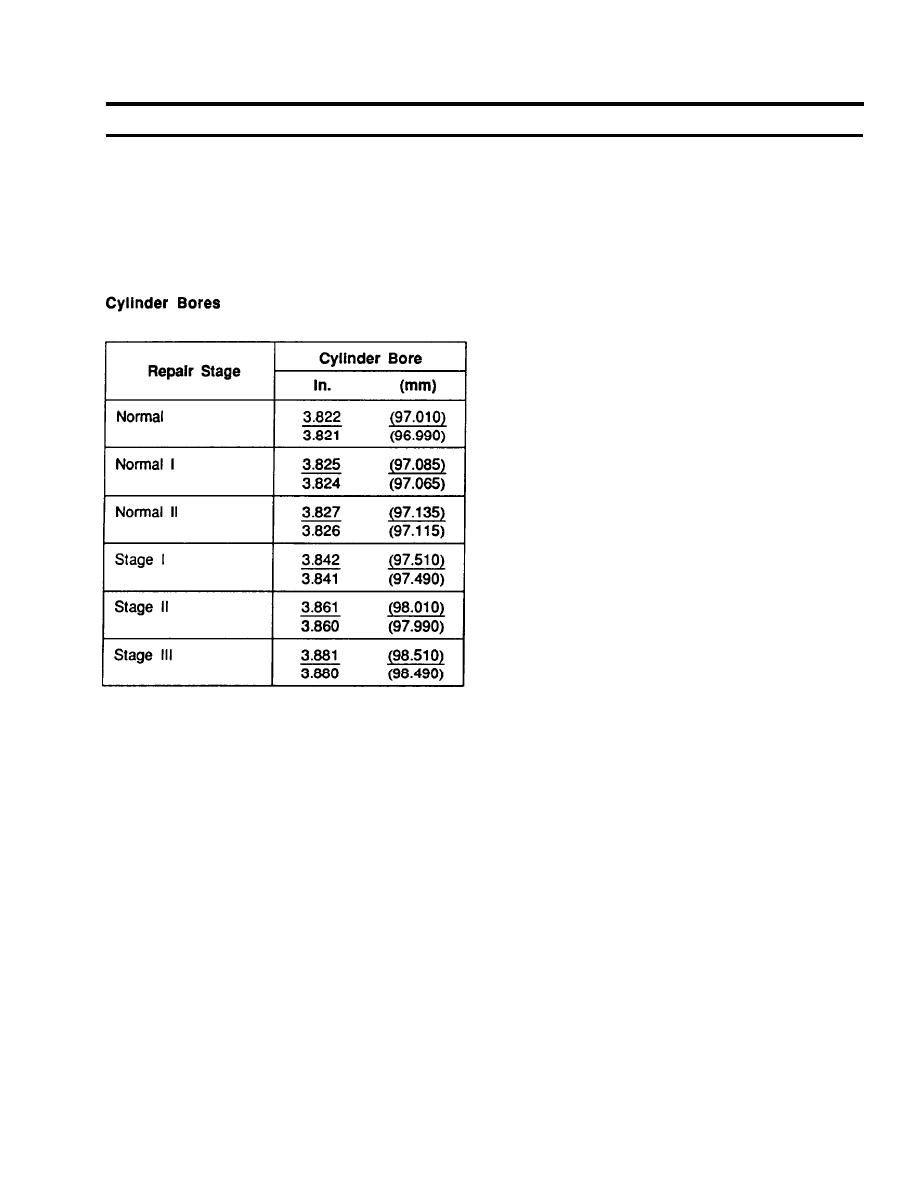

Measure inside diameter of each cylinder bore at two points 90 degrees apart, at six locations along

8.

length of bore. Maximum amount bore can be out-of-round or tapered is 0.0004 in. (0.01 mm). If

measurement is exceeded, tag crankcase for repair.

9.

Compare diameter measurements from step 8 with following table. If measurements are between repair

stages, tag crankcase for repair. If any measurement is larger than 3.881 in. (98.510 mm), replace

crankcase.

10. Inspect each cylinder bore for peaks and valleys. If any are present, measure distance between each

peak and valley. Acceptable depth of each valley is 0.0001-6.0002 in. (0.003-0.005 mm). If maximum

depth is exceeded, tag crankcase for repair. If repair would exceed maximum diameter shown in table,

replace crankcase.

11. Measure diameter of camshaft bearing bores. Diameter must be 2.364-2.365 in. (60.000-60.030 mm). If

any bore exceeds 2.365 in. (60.030 mm), replace crankcase.

13-51

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |