|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2420-224-34

PISTONS, RINGS, CONNECTING RODS, AND BEARINGS REPLACEMENT

(CONT)

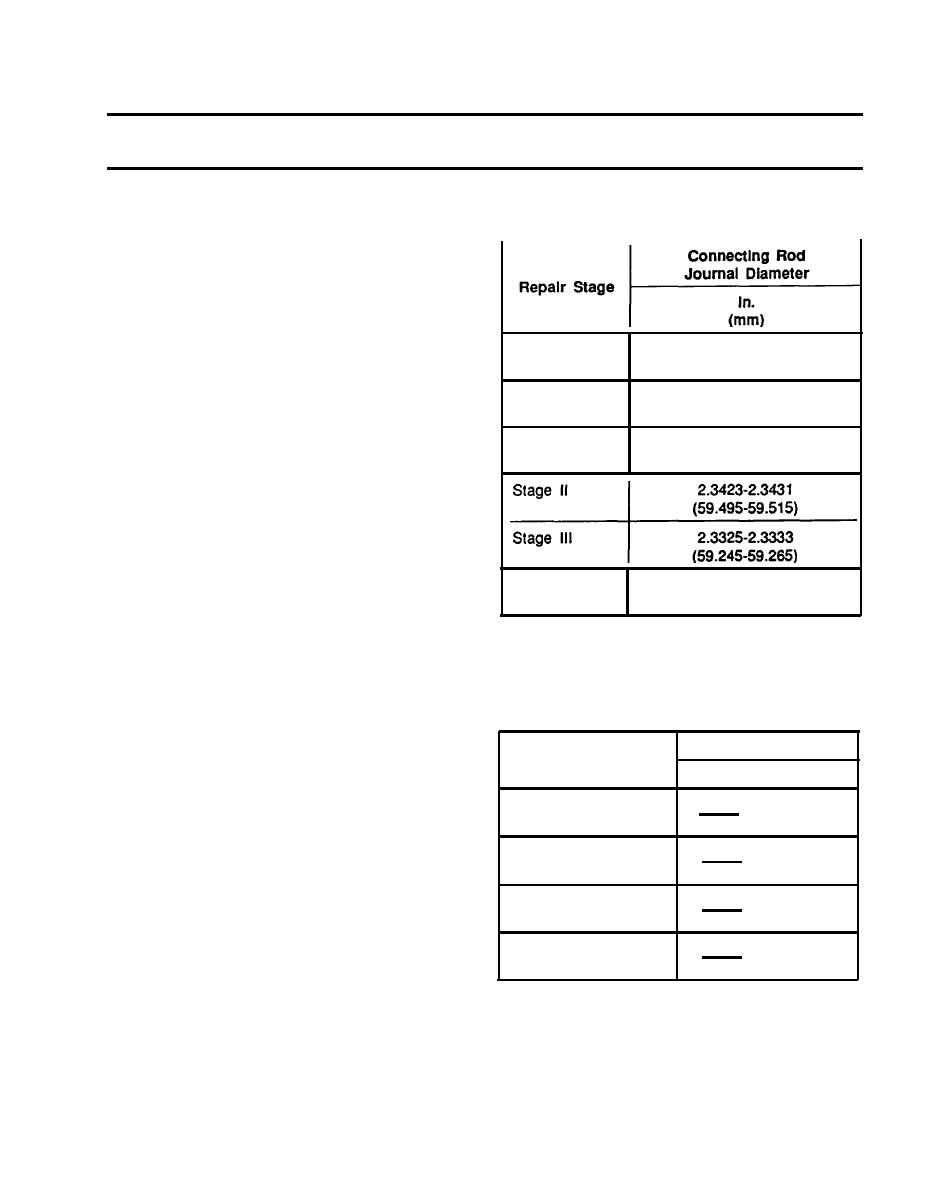

Crankshaft Repair Stage Specifications

If bushing measurement is acceptable, inspect

3.

bushing for scratches, gouges, nicks, and

cracks. If any of these conditions exist,

replace bushing.

2.3620-2.3628

Standard

(59.995-60.015)

4.

Measure connecting rod journals on crankshaft

and compare with following table. If any

2.3581-2.3588

Standard I

measurements are not within any stage listed,

(59.895-59.915)

remove crankshaft and tag for repair. Install

new crankshaft. If any measurements are less

2.3522-2.3530

Stage I

than lowest dimension in stage IV, reject

(59.745-59.7651

crankshaft assembly.

2.3226-2.3234

Stage IV

(58.995-59.015)

Piston Rings

Groove Width

Piston Ring No.

In.

(mm)

5.

Inspect pistons for excessive wear, burn

0.119

(3.030)

I

spots, cracks, and gouges. If any of these

0.118

(3.015)

conditions exist, reject piston assembly.

0.121

(3.060)

II

6.

C h e c k ring groove width. If not within

0.120

(3.045)

tolerance, reject piston.

0.121

(3.060)

Ill

0.120

(3.045)

0.218

(5.540)

Iv

0.217

(5.525)

13-33

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |