|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2420-224-34

BRAKE PRESSURE REGULATOR (ALB VALVE) ADJUSTMENT (CONT)

NOTE

I f adjustment setting cannot be

obtained and gage readings

fluctuate after rechecking, it may

be necessary to bleed brake

system (TM 5-2420-224-20) and

repeat Adjustment steps 1 thru 5.

Press brake pedal several times to activate

5.

brake system. Recheck gage reading for

proper pressure setting.

CAUTION

B e f o r e performing steps 6 thru

13, ALB fail-safe pressure

setting must be completed to

p r e v e n t damage to equipment.

Install spare tire (TM 5-2420-224-20).

6.

7.

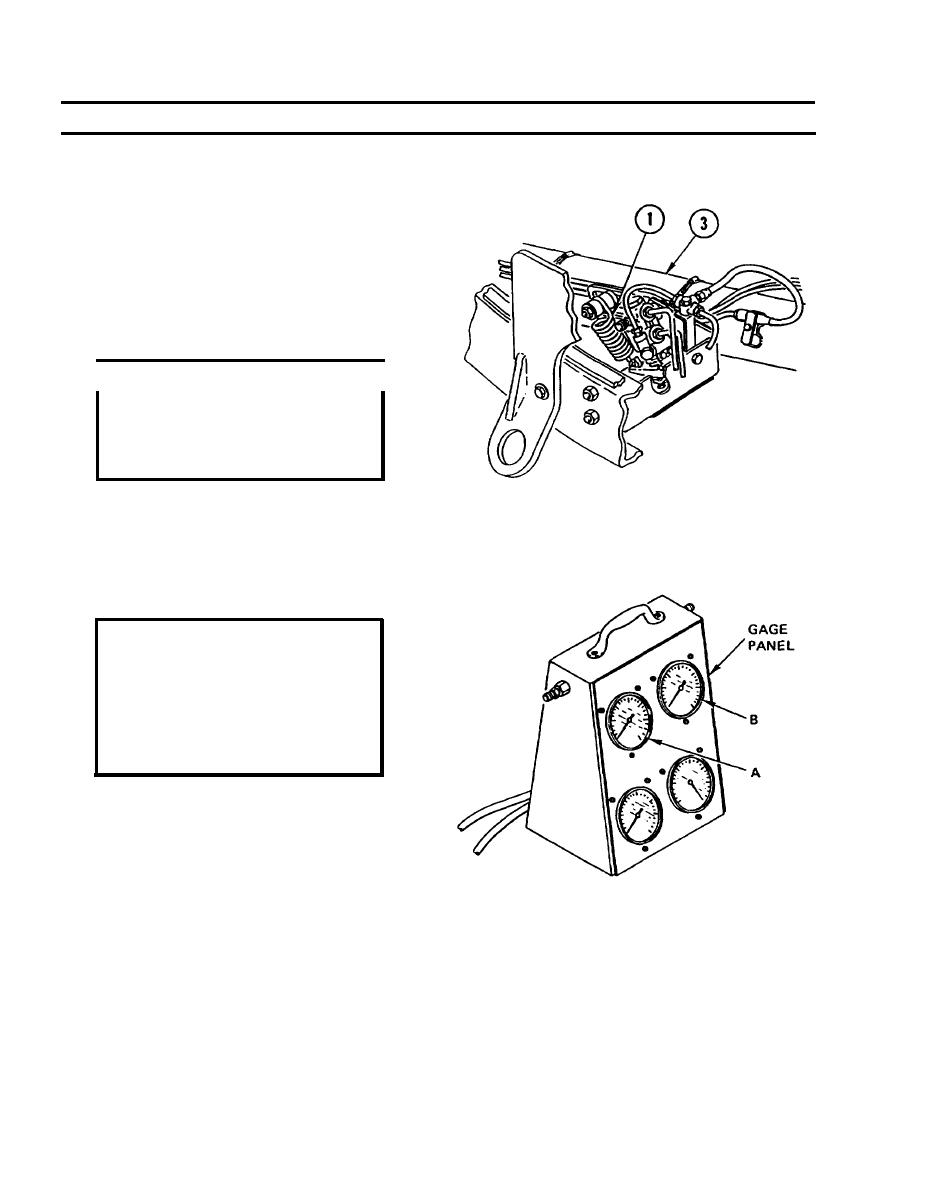

If removed, install control spring (1) to rear

torque tube (3) or retract outriggers.

Place backhoe (SEE) or crane (HMMH) in

8.

transport position (TM 5-2420-224-10).

CAUTION

Make sure air pressure of

vehicle brake system is not

below

90

psi

(6

bar)

as

i n d i c a t e d on air pressure gage

l o c a t e d on instrument panel to

p r e v e n t damage to equipment.

NOTE

Gage A indicates pressure of

modulated circuit 1. This pressure

is proportionate to rear axle load

with vehicle in transport position.

Position gage panel so gages can be read

9.

accurately. Slowly press brake pedal until full

pedal pressure is achieved. Both pressure

gages should rise until gage A reads modulated

rear axle load pressure setting of 1352 psi

(92 bar). Tolerance of 44 psi (3 bar) is

permissible. Gage B of unmodulated circuit

should read approximately 1924-2072 psi

(130-140 bar).

7-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |