|

| |

TM 5-2420-222-34

3-8.

CRANKSHAFT MAINTENANCE (Con’t).

NOTE

If one main bearing Is replaced, all main bearings must be replaced.

16.

If clearance Is not within specification and mating main bearing journal is within specification, replace main

bearings. Refer to Table 3-1 to determine what size bearings should be used.

17.

Remove two screws (2), washers (1), and main bearing cap (8) with attached lower sleeve bearing half (9) from

engine block (3). Remove lower sleeve bearing half from main bearing cap.

18.

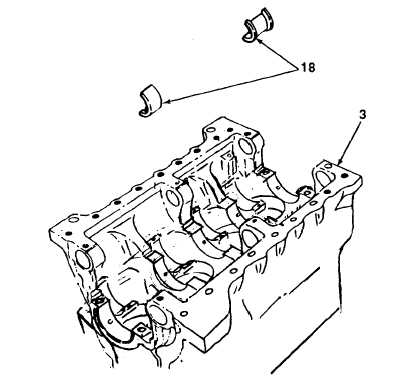

Remove upper sleeve bearing half (18) from engine block (3).

19.

If end play measurement taken In step 1 of removal is not within specification, replace upper and lower sleeve

bearing halves (9 and 18) in accordance with Table 3-1.

NOTE

Measurement of inside diameter of one connecting rod bearing Is described In

steps 20 through 29. Repeat steps for other connecting rod bearings.

20.

Pull connecting rod (11) and assembled piston (12) up In cylinder sleeve (13) until accessible.

TA701253

3-51

|