|

| |

TM 5-2420-222-34

14-3.

HYDRAULIC PUMP ASSEMBLY MAINTENANCE (Con’t).

8.

Start engine assembly and operate at high idle (see TM 5-2420-222-10).

9.

Check hydraulic pump and oil line connections for hydraulic fluid leaks.

10.

Shut down engine assembly (see TM 5-2420-222-10).

11.

Release hydraulic system pressure (see TM 5-2420-222-20).

12.

Remove backhoe valve box (see TM 5-2420-222-20).

13.

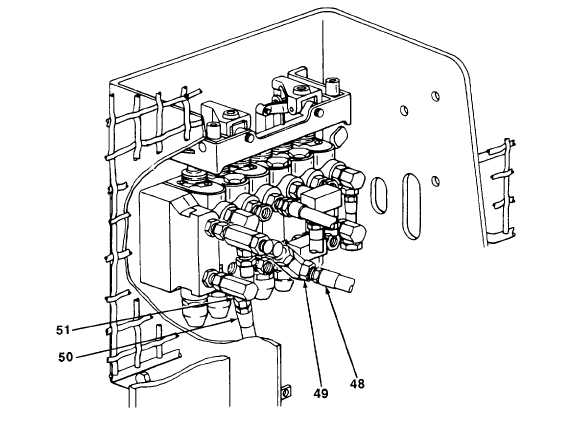

Disconnect oil line (48) from elbow (49).

14.

Install hydraulic system tester to elbow (49).

15.

Disconnect oil line (50) from adapter (51). Connect second line of hydraulic system tester to adapter.

16.

Start engine assembly and run at 1500 rpm until operating temperature is 170°F-190°F (770C-880C) (see TM 5-

2420-222-10).

17.

Check for leaks at connections. Tighten connections as required. If leaks stop, proceed to step 21.

18.

If leaking does not stop, shut down engine assembly (see TM 5-2420-222-10). Release hydraulic system

pressure (see TM 5-2420-222-10). Replace leaking elbow (49) or adapter (51).

TA701558

14-23

|