|

| |

TM 5-2420-222-34

14-3.

HYDRAULIC PUMP ASSEMBLY MAINTENANCE (Con’t).

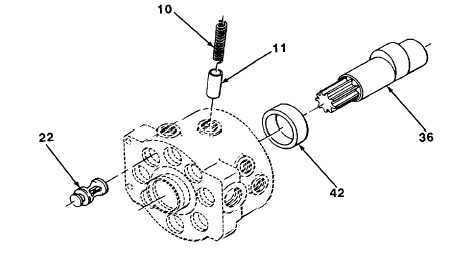

10.

Inspect eight pistons (11) for scoring and pitting. Using caliper, measure outside diameter of pistons.

Measurement must read 0.9360-0.9634 in. (23.7744-24.4704 mm).

11.

Using spring tester and torque wrench, check eight springs (10). If springs compress less than 47 lb.-ft. (64 N•m),

require more than 53 lb.-ft. (72 N•m), or vary more than 1.5 lb.-ft. (2 N•m), replace springs.

12.

Inspect eight inlet valves (22) for looseness. Using depth gage, measure lift. Measurement must read 0.0600-

0.0820 in. (1.5240-2.0828 mm).

13.

Using caliper, measure outside diameter of shaft (36). Measurement must read 1.7442-1.7448 in. (44.3027-

44.3179 mm).

14.

Using telescoping gage, measure inside diameter of outer bearing ring (42). Measurement must read 2.2458-

2.2465 in. (57.0408-57.0611 mm). Using caliper, measure outside diameter. Measurement must read 2.814-

2.816 in. (71.476-71.526 mm).

d.

ASSEMBLY

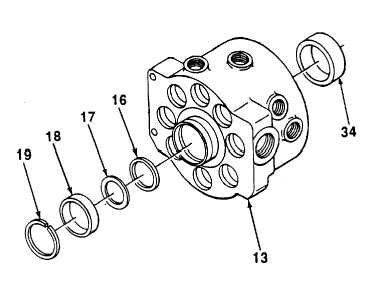

1.

Install new quad ring packing (16) and new

backup ring (17) in hydraulic pump housing (13).

CAUTION

Do not Install oil seal beyond retaining ring groove.

Improper Installation will cause leakage when

hydraulic pump Is assembled.

2.

Using driver, install new oil seal (18) in hydraulic

pump housing (13).

3.

Install retaining ring (19) in groove in hydraulic

pump housing (13).

4.

Using installer and arbor press, install bearing

cup (34) until seated in hydraulic pump housing

(13).

TA701553

14-18

|