|

| |

TM 5-2420-222-34

8-17.

REVERSER BRAKE HOUSING REPAIR (Con’t).

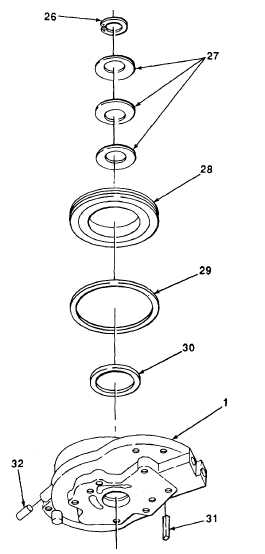

NOTE

Note how spring washers are stacked to ensure proper assembly.

16.

Slowly release pressure on modified oil filter cover (25) until spring washers (27) are loose. Remove modified oil

filter cover.

17.

Remove retaining ring (26), three spring washers (27), and piston

(28) from reverser brake housing (1). Discard spring washers.

18.

Remove seal ring (29) from piston (28).

19.

Remove preformed packing (30) from reverser brake housing (1).

Discard preformed packing.

20.

If damaged, remove grooved pin (31) and pin (32) from reverser

brake housing (1).

b.

CLEANING AND INSPECTION

WARNING

Dry cleaning solvent, P-D-680, Is toxic and flammable.

Always wear protective goggles and gloves, and use

only In a well-ventilated area. Avoid contact with skin,

eyes, and clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat. The

solvent's flash point Is 100°F-138°F (38 °C-59 °C). If

you become dizzy while using cleaning solvent,

Immediately get fresh air and medical help. If solvent

contacts eyes, Immediately wash your eyes and get

medical aid.

1.

Clean all metal parts with dry cleaning solvent. Dry thoroughly with

clean, dry rags.

2.

Inspect thrust washers, hub, gearshaft, carrier, and gears for

cracks, breaks, and missing or damaged teeth or splines. Replace

if defective.

3.

Inspect disk clutches with facing to ensure that grooved pattern is

not worn or chipped off, or internal teeth are not damaged.

4.

Inspect roller bearings (see TM 9-214).

TA701407

8-75

|