|

| |

TM 5-2420-222-34

7-1.

ENGINE AC GENERATOR REPAIR (Con’t).

NOTE

Semiconductor device diodes can be checked with

or without stator connecting leads soldered in place.

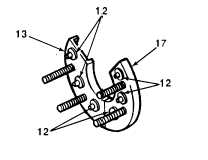

10.

Using multimeter, check diodes (12) for high and low

impedance readings. If high or low readings are identical for

all six diodes, semiconductor device (13 or 17) is okay. If

readings vary slightly, semiconductor devices are defective

and should be replaced.

NOTE

Loader backhoes with serial numbers 235786-235999 have Wye-connected stator

circuits. Loader backhoes with serial numbers 319995-342573 have Delta-

connected stator circuits.

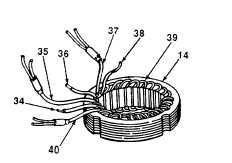

11.

Inspect windings (39) on stator (14 for shorts and damaged or

burned insulation.

NOTE

Steps 12 through 16 apply only to loader backhoes

with serial numbers 235786-235999.

12.

Using soldering gun and long round nose pliers, unsolder and

separate three winding ends (34, 36, and 38) on stator (14).

SERIAL NUMBERS 235786-235999

13.

Using multimeter, check for continuity between six winding ends (34 and 40, 35 and 36, and 37 and 38). If open

circuit is present, stator (14) is defective and must be replaced.

14.

Using multimeter check for continuity between stator (14) and three winding ends (34, 36, and 38. If continuity or

grounded winding exists, stator is defective and must be replaced.

15.

Using multimeter, check for continuity between winding ends (34 and 36, 36 and 38, and 34 and 38). If continuity

or short exists between winding (34, 36, and 38), stator (14) is defective and must be replace.

16.

Using soldering gun and long nose pliers, twist and solder together three windings (34, 36, and 38).

TA701337

7-7

|