|

| |

TM 5-2420-222-34

3-15.

IDLER GEARS REPLACEMENT (Con’t).

9.

Using vernier caliper, measure length of upper or lower idler gearshaft (3 or 14). Length must be 0.8680-0.8740

in. (22.0472-22.1996 mm).

10.

Inspect sleeve bearings for grooves. Using vernier calipers, measure inside diameter. Inside diameter must be

1.7520-1.7540 in. (44.5008-44.5516 mm). If damaged, replace upper or lower idler spur gear.

11.

If end play recorded in steps 2 and 11 of removal was not as specified and idler spur gears are within

specification, replace thrust washer bearing and washer.

d.

ASSEMBLY

NOTE

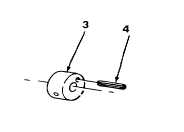

Step applies only if spring pin was removed.

Lower Idler gearshaft Is shown.

Tap spring pin (4) in lower idler gearshaft (3)

until spring pin extends beyond surface of shaft

0.200-0.280 in. (5.080-7.112 mm).

e.

INSTALLATION

1.

Install washer (13) in place on upper idler gearshaft (14) and spring pin (15).

2.

Lubricate upper idler gearshaft (14) and assembled parts with engine oil. Tap upper idler gearshaft in place in

cylinder block plate (1).

3.

Using timing alinement tool, aline timing marks on fuel injection pump helical gear (12), camshaft helical gear (25),

and crankshaft (23).

NOTE

When Installing upper idler spur gear, do not turn other gears.

4.

Lubricate sleeve bearing (17) in upper idler spur gear (16) with engine oil. Install upper idler spur gear and sleeve

bearing in place on upper idler gearshaft (14).

5.

Slide deflector (21) on crankshaft (23), then tap woodruff key (20) in place in crankshaft.

6.

Install thrust washer bearing (18) and bolt (19) in upper idler gearshaft (14). Torque bolt to 65 lb.-ft. (88 N•m).

TA701280

3-92

|