|

| |

TM 5-2420-222-34

3-13.

ROCKER ARM, SHAFT, AND PUSHROD MAINTENANCE (Con’t).

CAUTION

Rocker arms and rocker arm supports must be assembled in same position from

which they are disassembled. Improper assembly may damage parts.

3.

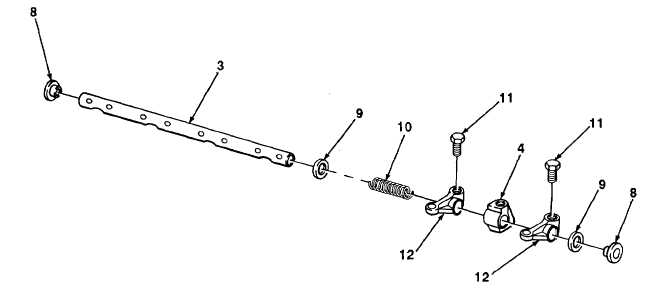

Tag and remove eight rocker arms (12), four rocker arm supports (4), and three springs (10).

4.

Remove eight adjusting screws (11) from rocker arms (12).

c.

CLEANING AND INSPECTION

WARNING

Dry cleaning solvent, P-D-680, is toxic and flammable. Always wear protective

goggles and gloves, and use only In a well-ventilated area. Avoid contact with

skin, eyes, and clothes, and DO NOT breathe vapors. DO NOT use near open

flame or excessive heat. The solvent's flash point Is 100°F-138°F (38°C-590C). If

you become dizzy while using cleaning solvent, Immediately get fresh air and

medical help. If solvent contacts eyes, Immediately wash your eyes and get

medical aid.

1.

Clean parts with dry cleaning solvent, nonelectrical wire, and abrasive cloth, then dry thoroughly with a clean, dry

rag.

2.

Inspect parts for cracks, bends, or breaks. Replace defective parts.

3.

Using micrometer, check outside diameter of rocker arm shaft at wear points. Outside diameter must be 0.7869-

0.7899 in. (19.9873-20.0635 mm). Replace if defective.

4.

Using calipers, check bore diameter of eight rocker arms. Bore diameter must be 0.7900-0.7940 in. (20.0660-

20.1676 mm). Replace if defective.

5.

Using spring tester and torque wrench, compress three springs to 1.8125 in. (46.0375 mm) and note compression

force on torque wrench. Compression force must be 48-72 lb.-ft. (5.4-8.1 N•m). Replace if defective.

TA701273

3-83

|