|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM5-241O-237-34

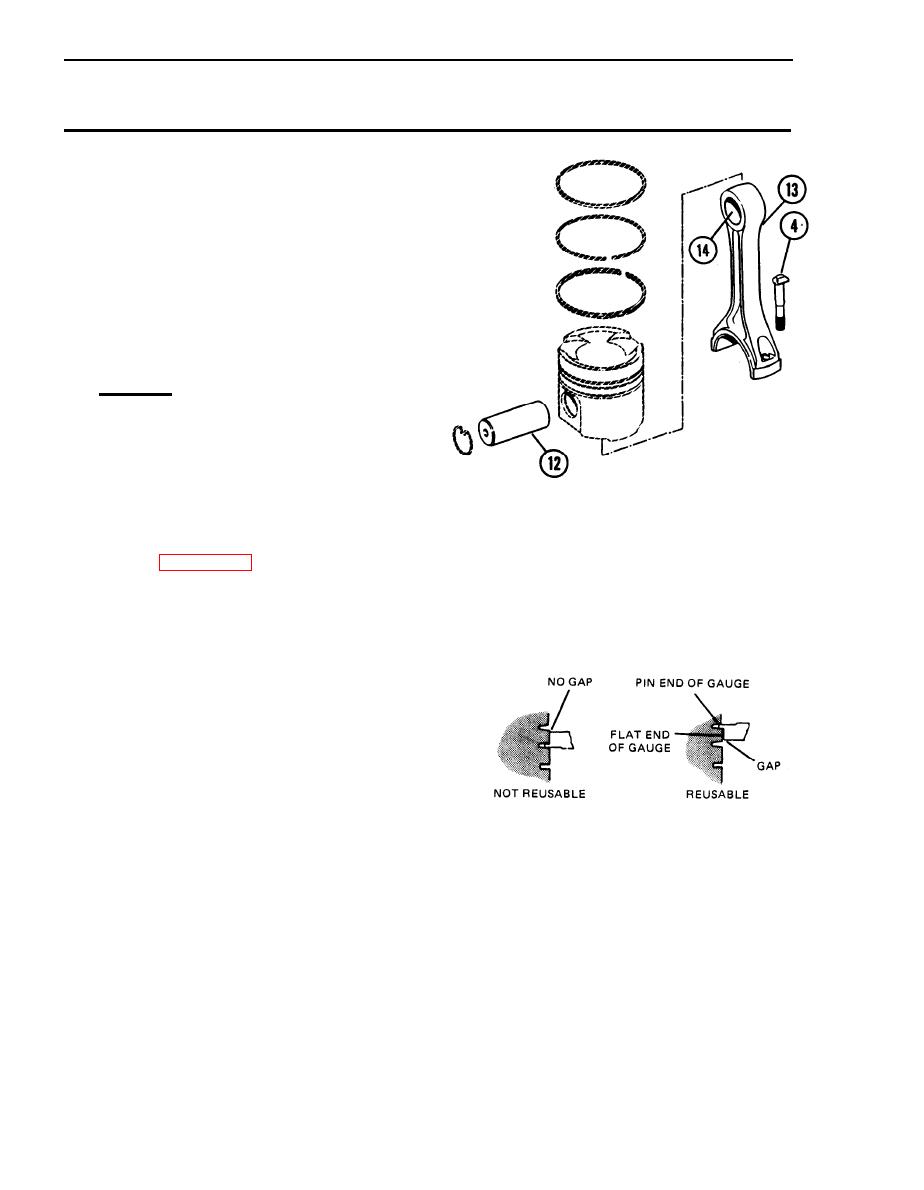

3-18. PISTONS, CONNECTING RODS, PISTON PINS AND RINGS -

REPLACE/REPAIR (Cont'd)

(12) Check the piston pin bearing bore

diameter after the bearing (14)

is installed. The correct

dimension is 1.70120.0003 in.

The maximum permissible clearance

between the bearing and piston

pin (12) must not be more than

0.003 in.

(13) If necessary, remove two

capscrews (4) from connecting

rod (13).

c.

Assembly

(1) If it was necessary to remove two

capscrews (4), install them on

connecting rod (13).

(2) When old pistons are used, clean

the piston grooves with an

acceptable ring groove tool.

(3) See Table 3-4 for correct piston

and ring clearances.

(4) It is necessary to measure the

grooves in pistons with a

Keystone piston ring groove

gage. Put the pin end of in the

groove at four places around the

Do this to both

circumference.

grooves. The flat edge of the

gage must be between grooves for

the top ring and intermediate

ring. If there is clearance

between the flat edge of the

gage and the piston at all test

locations, for both grooves,

reuse the piston. If the flat

edge is in contact with the

piston, at any of the test

locations, do not reuse the

piston. Install a new piston.

3-80

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |