|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

WINCH ASSEMBLY REPAIR - CONTINUED

0245 19

ASSEMBLY - CONTINUED

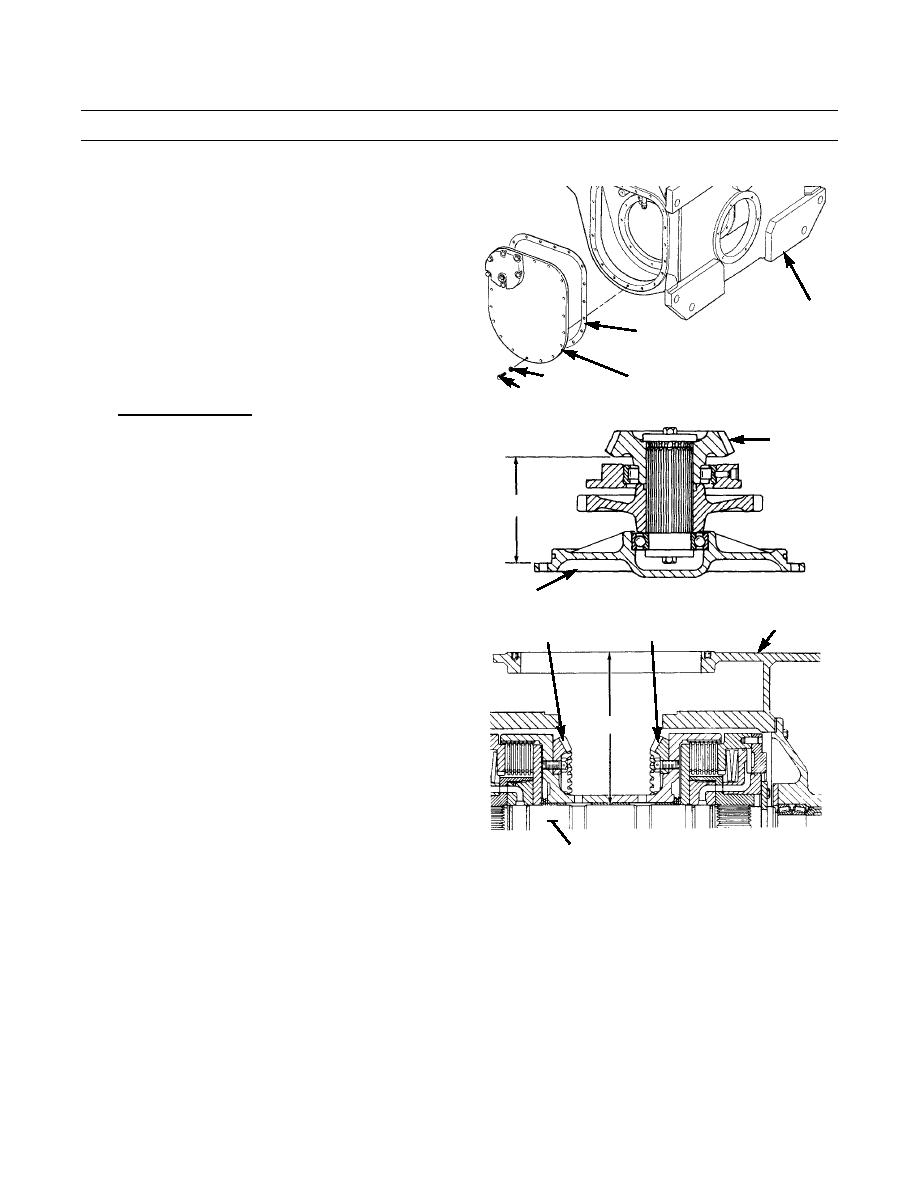

bg. Install new gasket (154) and access cover (153)

to case (5) with 15 new lockwashers (152) and

bolts (151). Tighten bolts to 36 lb-ft (49 Nm).

5

154

152

153

421-0219

151

3.

Install Winch Pinion.

a.

Remove three bolts (115), bearing cage (116)

127

and pinion assembly from case (5).

b.

Measure and record dimension (B) between

mounting surface of bearing cage (116) and back

B

face of pinion gear (127).

PINION ASSEMBLY

421-0317

116

c.

Measure and record dimension (C) between face

5

200

200

of case (5) and clutch shaft (155) through gap

between two clutch housings.

C

421-0318

155

d.

Calculate difference between dimension (B) in step b and dimension (C) in step c.

e.

Subtract difference found in step d from 4.375 in. (111.13 mm), to determine thickness of shims (117) needed to

obtain correct free movement (backlash) between pinion gear (127) and bevel gears (200), when pinion assembly

is installed.

0245 19-29

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |