|

|||

|

|

|||

|

Page Title:

CLEANING AND INSPECTION - CONTINUED |

|

||

| ||||||||||

|

|

TM 5-2410-237-23

CAMSHAFT AND CAMSHAFT BEARINGS REPLACEMENT - CONTINUED

0245 06

CLEANING AND INSPECTION - CONTINUED

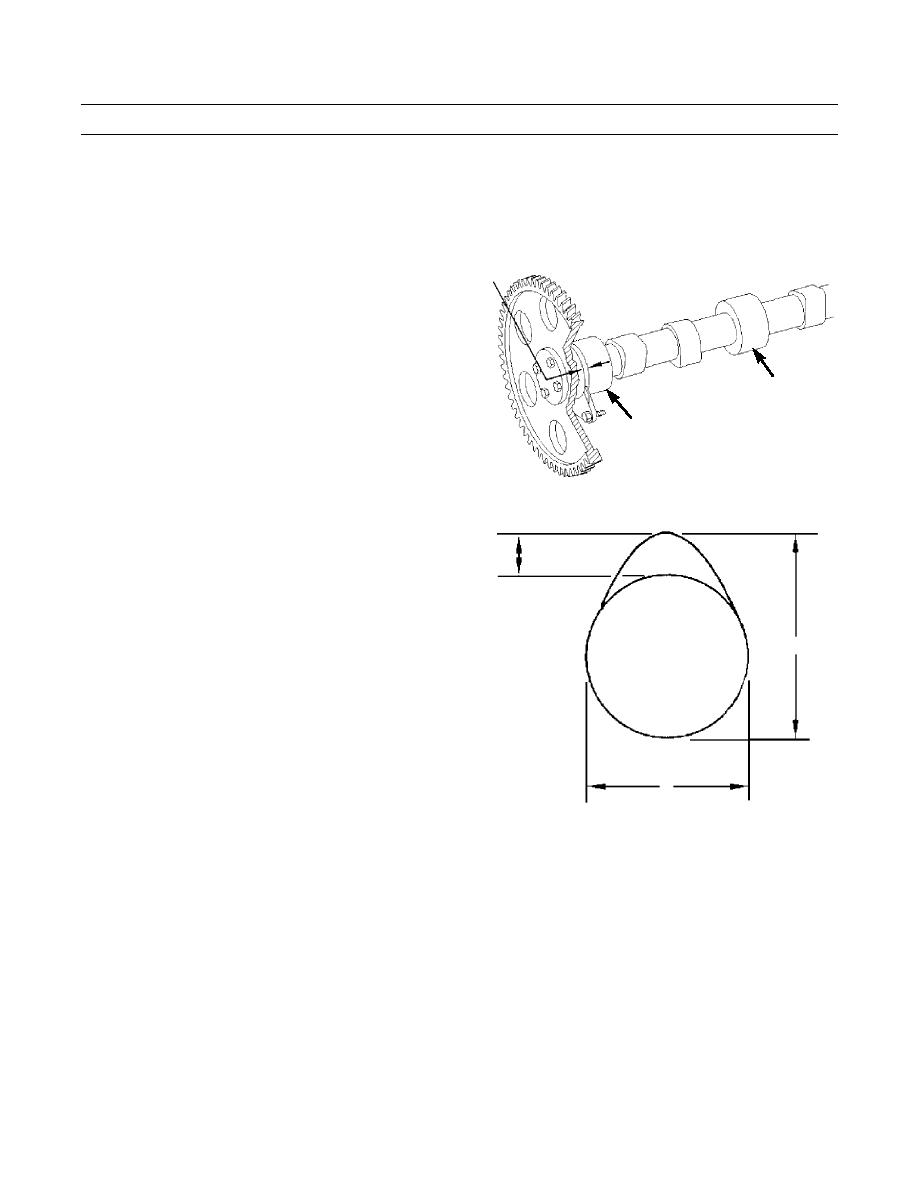

4.

Perform the following checks:

a.

Width of groove in the camshaft for new thrust washer (12) should be 0.19 0.005 in. (4.83 0.13 mm). Thick-

ness of new thrust washer should be 0.183 0.001 in. (4.65 0.03 mm). End play of new camshaft should be

0.007 0.003 in. (0.18 0.08 mm). Maximum permissible end play of a worn camshaft is 0.025 in. (0.64 mm).

b.

Diameter of a new camshaft bearing journal sur-

12

face (13) should be 2.311 0.0005 in. (58.699

0.013 mm).

c.

Bore (14) in bearing for new camshaft should be

2.315 0.002 in. (58.8 0.006 mm). Clearance

between new bearing and bearing journal surface

is 0.001 to 0.007 in. (0.03 to 0.17 mm). Maxi-

13

mum permissible clearance between worn bear-

ing and the bearing journal surface is 0.008 in.

14

(0.20 mm).

421-0140

5.

Determine camshaft lobe lift:

a.

Measure camshaft lobe height (B).

D

b.

Measure base circle (C).

c.

Subtract the base circle in step b from lobe

height in step a. The difference is the actual lobe

lift (D).

B

d.

Specified camshaft lobe lift (D) for exhaust and

inlet lobes are 0.33 in. (8.38 mm).

e.

Maximum permissible difference between the

actual lobe lift in step c and the specified lobe lift

in step d is 0.025 in. (0.64 mm).

C

421-0141

Change 1

0245 06-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |