|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

CRANKSHAFT AND BEARINGS ASSEMBLY MAINTENANCE - CONTINUED

0245 03

INSTALLATION - CONTINUED

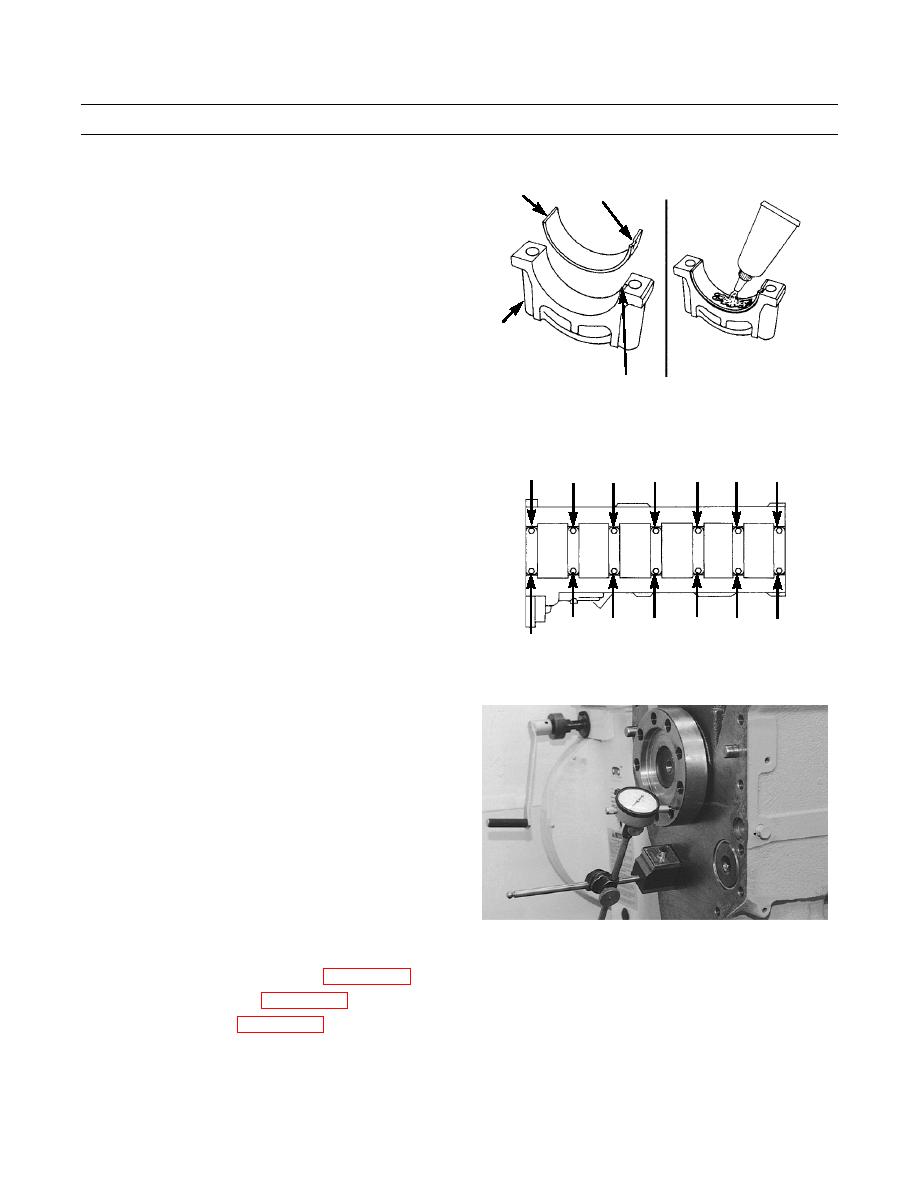

9.

Install seven new lower main bearing shells (6) with

BEARING TANG

6

bearing tang in slot of main bearing cap (5). Apply

clean oil on mating surfaces.

5

BEARING

421-0096

CAP SLOT

10.

Perform steps 4 and 5 for the remaining bearing caps.

14

6

7

11

2

3

10

Tighten bearing caps in sequence shown.

4

1

9

5

8

12

13

421-0094

11.

Turn crankshaft by hand. If crankshaft does not turn

freely, loosen main bearing capscrews one at a time to

locate tight bearing and replace if necessary.

12.

Check crankshaft end play with a dial indicator. End

play is controlled by the thrust plates on the rear main

bearing. End play with new thrust plates is 0.048 to

0.0228 in. (1.219 to 0.579 mm). Maximum end play

with used thrust plates is 0.025 in (0.64 mm).

421-0093

13.

Install pistons and connecting rods (WP 0245 04).

Install flywheel housing (WP 0031 00).

14.

15.

Install front housing (WP 0245 05).

END OF WORK PACKAGE

0245 03-10

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |