|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

RIPPER LIFT CYLINDER REPAIR - CONTINUED

0224 00

ASSEMBLY - CONTINUED

NOTE

Do NOT allow bearing mount compound to contact sealing lip.

6.

Apply bearing mount compound evenly but not excessively to counterbore of head (1) and to metal shell of seal (19).

7.

Install seal (19) into counterbore of head (1), with sealing lip facing inward. Seat seal firmly against bottom of counter-

bore. Wipe away excess bearing mount compound. Allow compound 15 minutes to dry.

8.

If removed, install bearing sleeve (18) in head (1).

9.

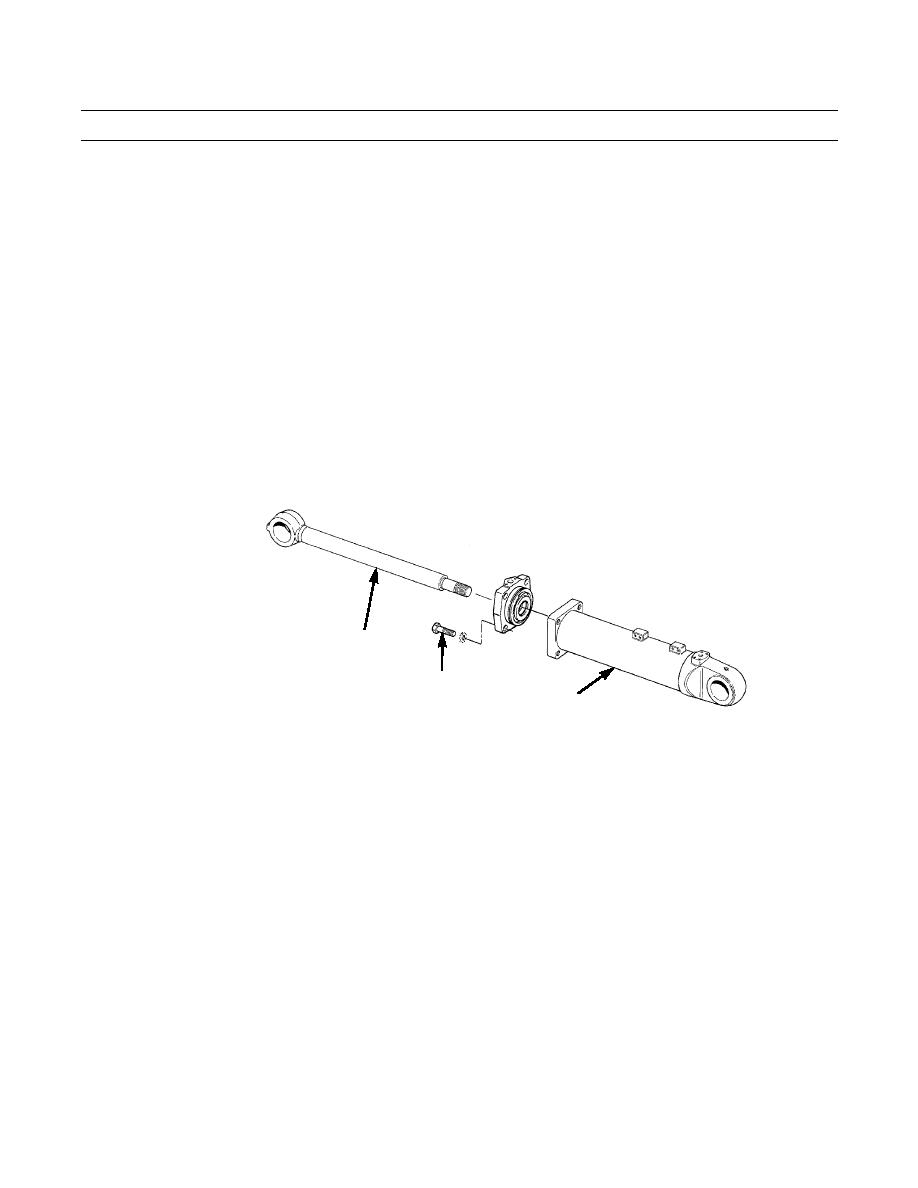

Place head (1) on cylinder housing (2) and install two bolts (11) to hold head in place.

CAUTION

Piston rod must be supported and kept level at all times to avoid damaging seals in head.

10.

Place seal guide on piston end of piston rod (13). Push piston rod into head (1) as far as possible.

11.

Remove two bolts (11) and separate head (1) and piston rod (13) as a unit from cylinder housing (2).

13

11

2

387-730

0224 00-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |