|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

TRACK ASSEMBLY INSPECTION AND ADJUSTMENT - CONTINUED

0132 00

ADJUSTMENT - CONTINUED

WARNING

Wear eye protection and keep face clear when venting grease from relief valve during track adjustment.

NEVER visually inspect relief valve to see if grease is escaping. Always observe track to verify it has loos-

ened. Failure to follow this warning could cause eye injury or blindness.

4.

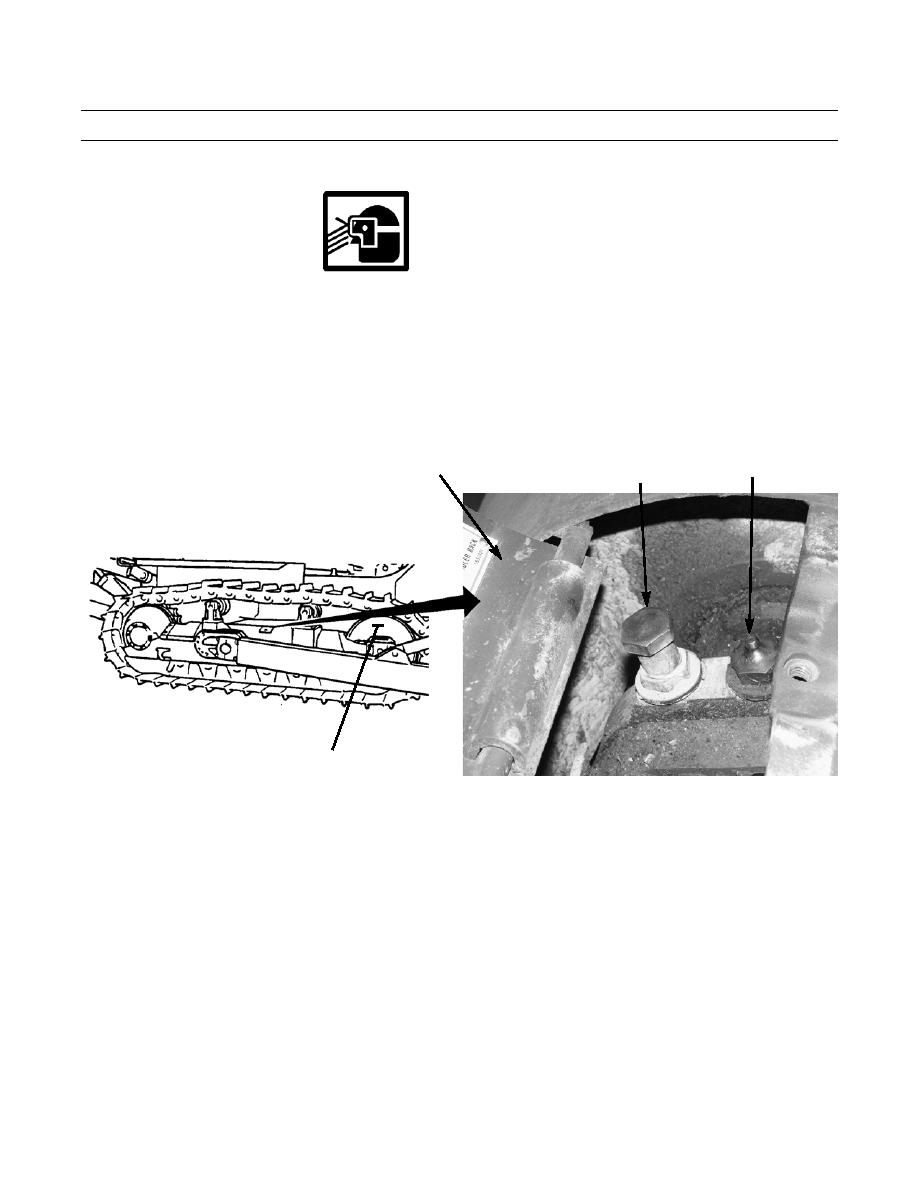

Open relief valve (2) and allow grease to escape and track tension to release.

5.

Close relief valve (2). Clean area around relief valve and fill valve (3)

6.

Connect grease fun to fill valve (3). Pump grease into fill valve until track idler (4) moves forward toward front of trac-

tor. STOP pumping when track idler stops moving.

1

3

2

4

387-924

7.

Mark a line on track roller frame (5) 1/2 in. (13 mm) from rear face of idler bearing support (6).

0132 00-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |