|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

ENGINE ASSEMBLY REPLACEMENT - CONTINUED

0021 00

INSTALLATION - CONTINUED

WARNING

Use extreme caution when handling heavy parts. Provide adequate support and use assistance during pro-

cedure. Ensure that any lifting device used is in good condition and of suitable load capacity. Keep clear of

heavy parts supported only by lifting device. Failure to follow this warning may result in death or injury to

personnel.

CAUTION

Always use a load leveler when lifting engine assembly. This will keep lifting force vertical at all times,

avoiding damage to lifting brackets.

Engine assembly must be lifted so that crankshaft centerline is horizontal. This will prevent binding on

rear engine mounts locating pins.

NOTE

Weight of engine and torque divider is approximately 3,000 lb (1,362 kg).

If equipped, A/C components must be transferred to replacement engine (WP 0233 03).

3.

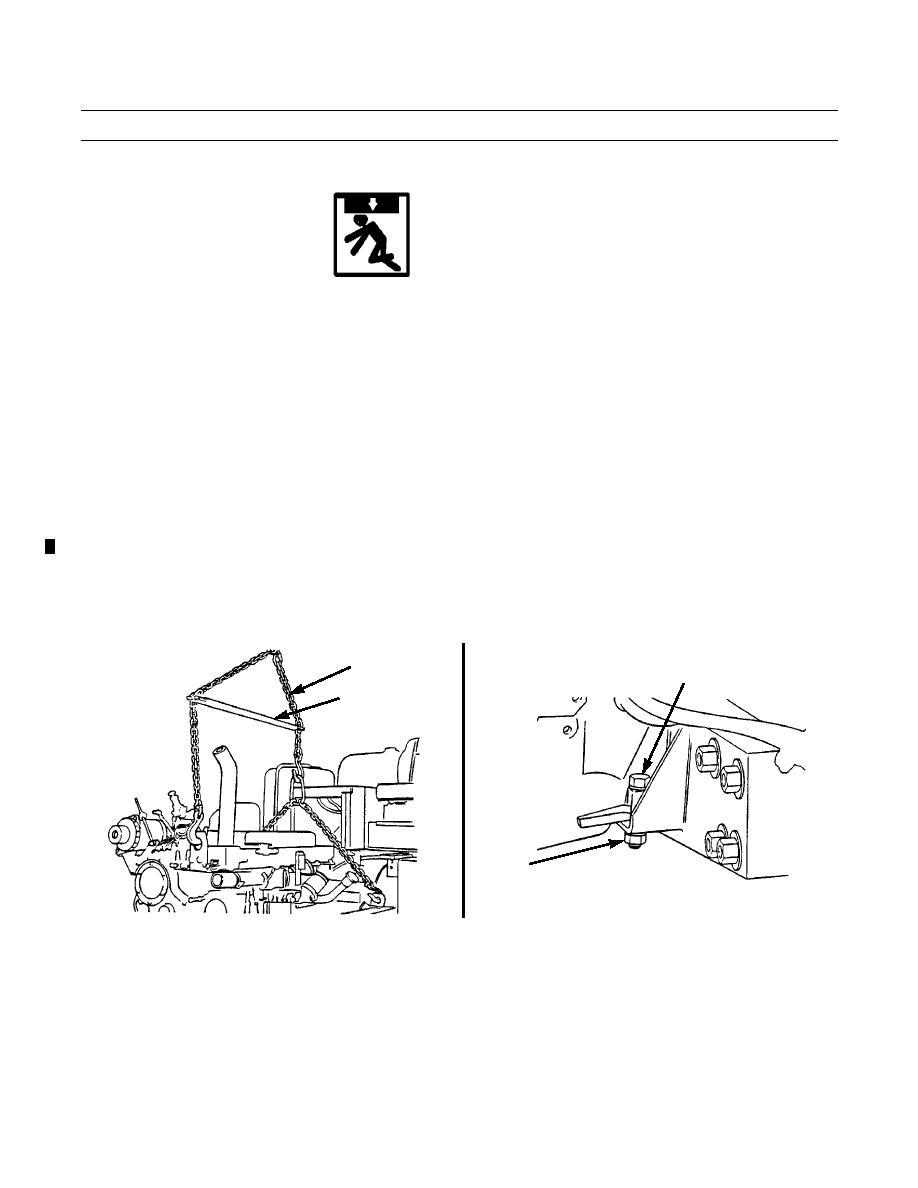

Attach load leveler and lifting device (61) to three brackets on replacement engine. Install engine in machine, keeping

crankshaft centerline horizontal. Make sure rear engine mounts fit onto locating pins (63) in frame.

4.

Install two capscrews (58), washers (60) and nuts (59) into front engine mounting bracket. Tighten capscrews to 325 lb-

ft (441 Nm).

61

58

LOAD

LEVELER

59,60

387-084

387-089

0021 00-9

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |