|

|||

|

|

|||

|

Page Title:

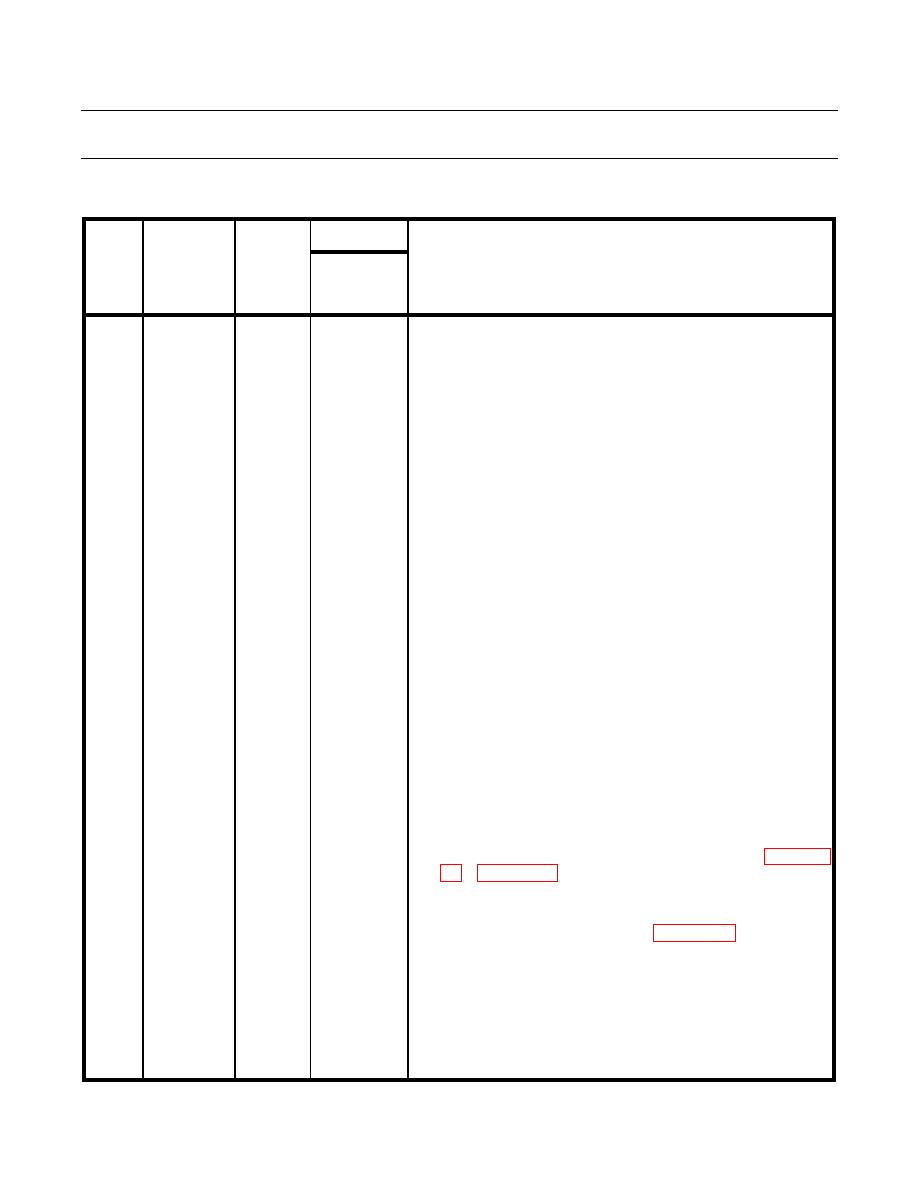

Table 1. Unit Maintenance Preventive Maintenance Checks and Services (PMCS) for the D7G Tractor. - Continued |

|

||

| ||||||||||

|

|

TM 5-2410-237-23

UNIT MAINTENANCE PREVENTIVE MAINTENANCE CHECKS AND

SERVICES (PMCS) - CONTINUED

0010 00

Table 1. Unit Maintenance Preventive Maintenance Checks and

Services (PMCS) for the D7G Tractor - Continued.

LOCATION

ITEM TO

ITEM

MAN-

CHECK/

NO.

INTERVAL

HOURS

SERVICE

PROCEDURE

10

f.

Operate all machine implements and note response of respective

control levers.

(Con't)

g.

Lightly apply brake pedals with steady force. Machine should

slow down immediately and stop smoothly.

h.

Park machine on level ground. Place transmission in N (Neu-

tral) with transmission lock lever in locked position. Engage

brake lock lever. Lower implements to the ground and shut

down engine.

i.

Perform a walk around inspection of machine. Check for evi-

dence of leaks: oil, fuel and engine coolant.

j.

Ensure all data, caution and warning plates are present, securely

mounted and legible.

11

Semiannual

Engine

a.

Inspect oil lines and hoses for cracks, frays and wear that could

cause leaks.

b.

Ensure engine oil filter assembly is securely mounted with no

evidence of leaks.

c.

Inspect rocker arm (valve mechanism) cover for damage and

leaks.

d.

Inspect all engine compartment wiring for frays, splits, missing

insulation and poor connections. Replace any damaged wires

and tighten any loose connection.

12

Semiannual

a.

Inspect fuel filter housings for dents and cracks that could cause

leaks.

b.

Inspect fuel transfer pump, fuel lines and fittings for damage

and leaks.

c.

Service primary and secondary fuel filter assemblies (WP 0059

00 or WP 0060 00).

d.

Remove fuel filler cap and strainer. Disassemble filler cap and

clean strainer and filler cap components. Assemble filler cap

and reinstall strainer and filler cap (WP 0052 00).

0010 00-4

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |