|

|||

|

|

|||

|

Page Title:

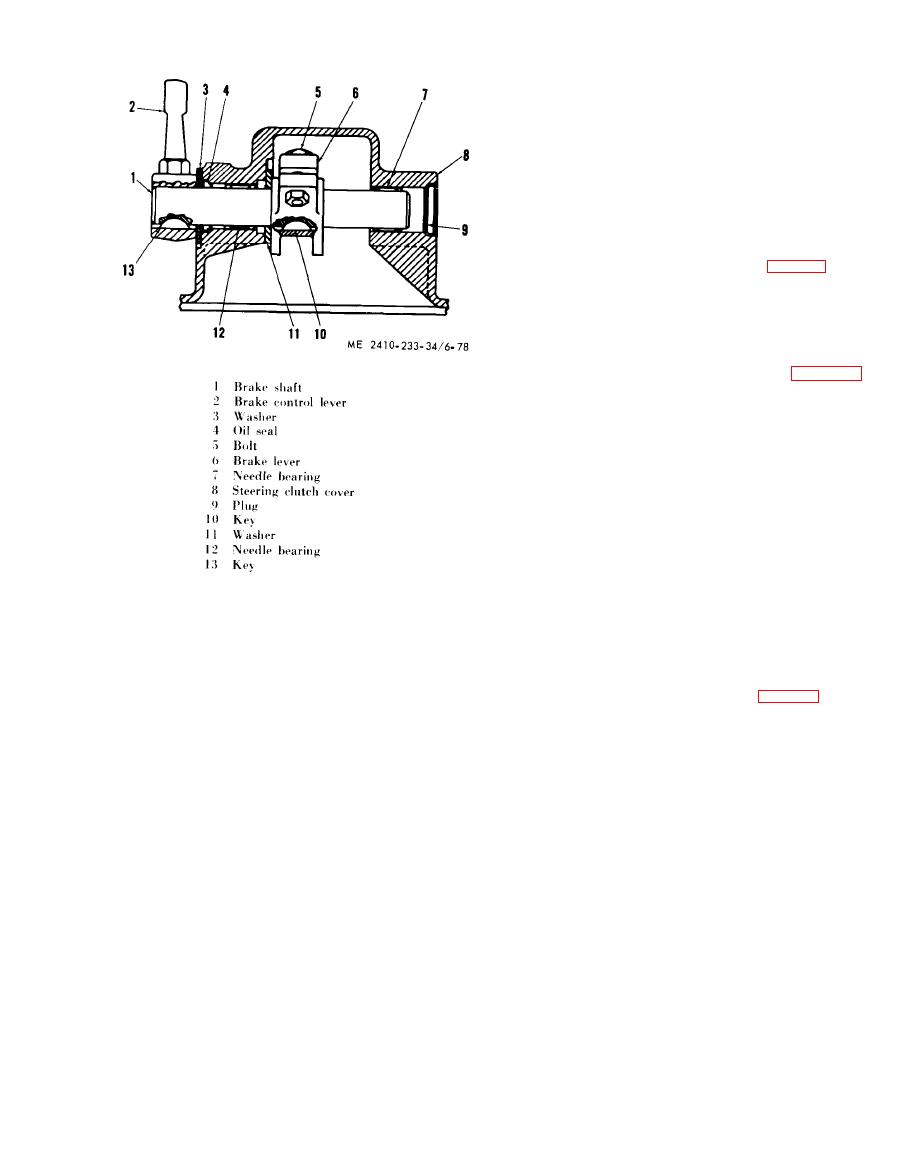

Figure 6-78. Disassembling clutch cover brake linkage. |

|

||

| ||||||||||

|

|

(5)

Inspect

the

brake

drums

for

scoring,

dam age and

wear.

Replace

a

damaged,

badly

scored, or excessively worn drum.

NOTE

Steeering brake drums which are not scored, cracked, or

otherwise damaged, may be considered serviceable

from the wear standpoint, if the following conditions is

met: after installing new brake linings, at least one

half of the band adjustment travel must remain. If one

half or more of the adjustment travel does not remain.

replace the drum.

(6) Inspect washers (3) and (11), fig. 6-78, for

dam age and wear. Replace if damaged or worn

excessively.

( 7 ) Inspect all springs for cracks, breaks, and

distortion. Replace defective springs.

e. Adjustment.

( 1 ) Install a wood block as shown in figure 6-

7 9 and turn the adjusting screw clockwise until the

lever assemblies are firmly against their stops.

(2)

Lift

brake

link

with

a

pull

of

ap-

proximately 30 pounds.

( 3 ) Measure the distance "A" from the top of

the pin, which joins the brake link to the brake

toggle links, to the milled flat on the support

assembly.

(4) Add or remove shims behind the stop to

o b t a i n a distance "A" of 0.860 inch to 0.900 inch.

( 5 ) Install the support assembly in the steering

clutch and bevel gear case (subpara a a b o v e ) .

(6) Turn the adjusting screw socket assembly

d. Inspection and Repair.

u n t i l the brake band is tight on the steering clutch

( 1 ) Inspect all supports, links, levers, and pins

o u t e r drum. Back off the socket assembly 1 1/2 t u r n s

for cracks, breaks, distortion and wear. Repair by

or nine clicks.

welding, straightening, or replace the part.

(7) Install the remaining brake linkage.

(2) Inspect all needle bearings for corrosion,

( 8 ) The parking brake lever (1, fig. 6-80) can

roughness, and wear. Replace damaged or ex-

be adjusted by disengaging the parking brake and

cessively worn bearings.

adjusting the parking brake linkage (4) to obtain

( 3 ) Inspect all sleeve bearings for damage and

dimension (B), which is the distance between the

wear. Sleeve bearing to pin clearance (new) is

front face of the seat arm rest support and cen-

approximately 0.003 to 0.005 inch. The maximum

t e r l i n e of parking brake lever (0.82 to 0.94 inches).

clearance is 0 . 0 1 5 i n c h . Replace

allowable

T h e brake pedal (2) can be adjusted by disengaging

damaged or excessively worn bearings or pins.

the parking brake and adjusting the brake linkage

(4) Inspect the brake linings for damaged or

( 3 ) to dimension (C) which is the distance between

w o r n condition. Replace the linings if damaged or

t h e front face of the seat support and the rear face

w o r n to within 3 / 32 inch of rivet heads.

of the brake pedal (17.63 to 17.87 inches).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |