|

|||

|

|

|||

|

Page Title:

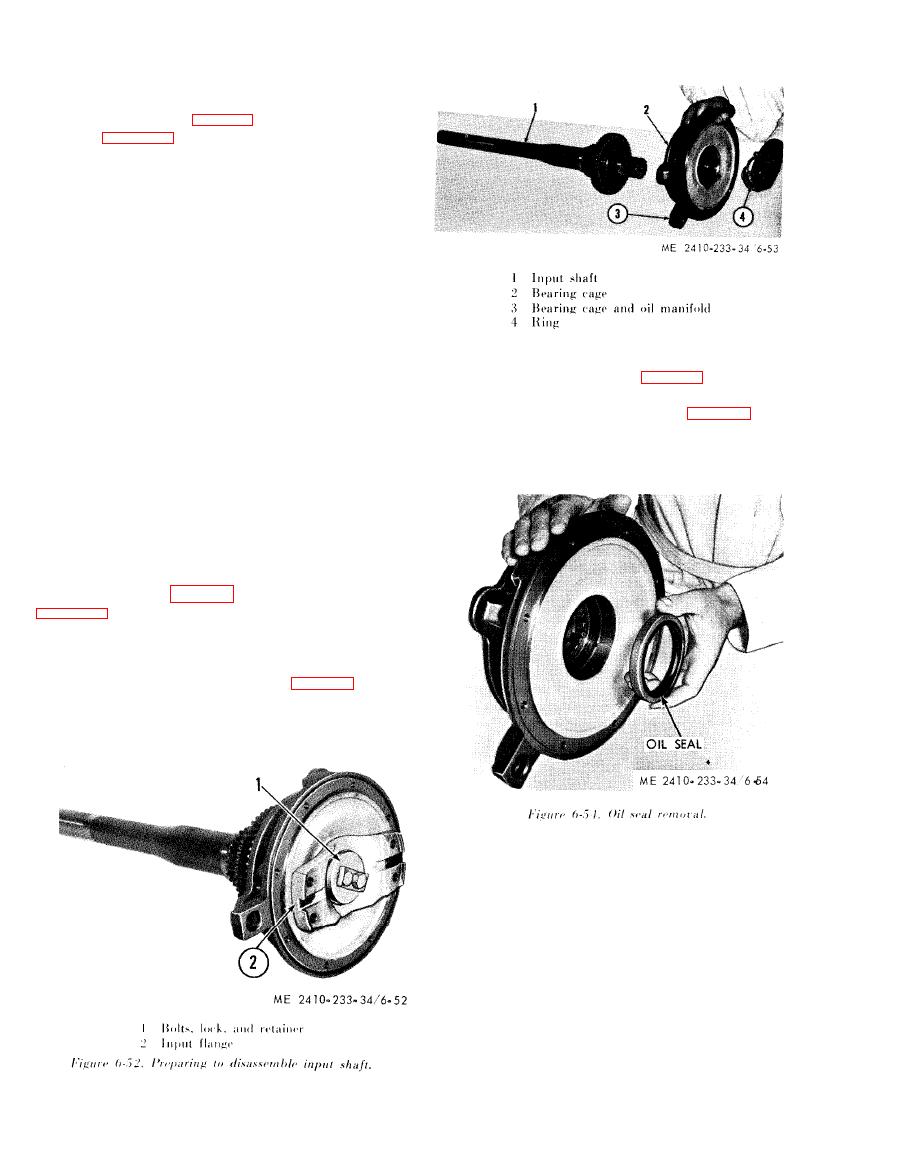

Figure 6-53. Bearing cage removal. |

|

||

| ||||||||||

|

|

(11) Inspect and replace all worn parts before

assembling

the transmission. At the time of

assembly tighten the No. 2 carrier to bearing cage,

retaining bolts (2, 3, fig. 6-50) to the torque value

listed in table 1-2.

(12) All worn, damaged, or warped clutch

plates and disc assemblies should be replaced when

i n s t a l l i n g the clutches.

CAUTION

When installing the clutches, install the

c l u t c h housing first, then install the ring

gear

followed

by

a

disc

assembly

and

plate alternately (subpara j below) for

the correct number of disc assemblies

and plates for each clutch. Make certain

the clutch reaction pins are in their

proper location and the springs are

seated correctly. The ring gear for the

(3) Remove the oil seal (fig. 6-54) by tapping

No. 5 clutch should be installed with the

it from the rear with a small block of wood.

face having the smaller outer diameter

(4) Remove the retainer ring (fig. 6-55).

t o w a r d t h e i n p u t e n d of the trans-

NOTE

mission. The clutch housing for the No.

The

oil

seal

is

correctly

installed

with

the

spring-loaded

1

clutch

is i n s t a l l e d i n v e r t e d

with

lip toward the rear of the the transmission.

respect

to

other

clutches.

the

In-

stallation of the clutch housings can be

facilitated by using three of the long

retaining bolts as guide pins.

( 1 3 ) Complete the installation in the reverse

order of removal and tighten the clutch housing

r e t a i n i n g bolts (1, fig. 6 - 4 7 ) to the value given in

g. Input Shaft Disassembly and Assembly.

(1) Remove bolts, lock, and retainer (1, fig. 6-

52), and input flange (2).

( 2 ) Slide the bearing cage (2, fig. 6-53) and

b e a r i n g cage and oil manifold (3) from the input

s h a f t (1) while removing the ring (4) at the same

time.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |