|

|||

|

|

|||

|

Page Title:

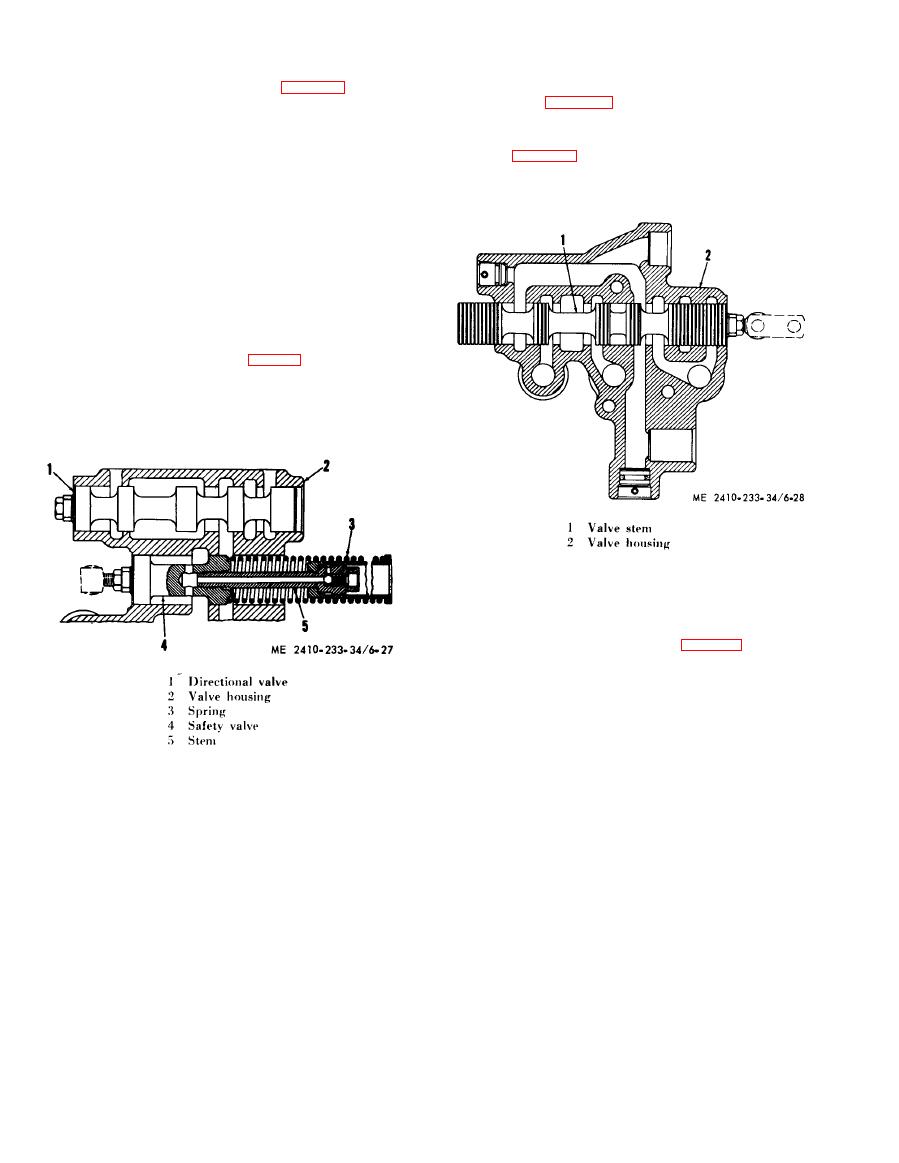

Figure 6-27. Safety and directional valve disassembly. |

|

||

| ||||||||||

|

|

L i q u i d Lock on threads of valve stem (5), install

(3) P r e s s u r e c o n t r o l v a l v e r e a s s e m b l y .

valve stem into valve (4), and tighten to torque

v a l u e listed in table 1-2. Do not hold valve (4) by

(13), and retainer (12), into piston (15), and secure

finished lands.

i n place with retainer ring (11).

(5) Speed selector valve. S p e e d s e l e c t o r v a l v e

(b) I n s t a l l s l u g ( 1 0 ) i n t o p i s t o n ( 1 5 ) .

stem (1, fig. 6-28) can be removed from valve

(c) Install pistons (2) and (15) and stops

housing (2) if necessary.

(1), (9), and (16), into housing (3). Secure stops in

d.

Linkage

Adjustment.

place with pins.

(d) Install piston (6), retainer (5), and

piston (18), into housing (7).

NOTE

Install

spacers

(19)

inside

piston

(18).

(e) With

springs

(4)

and

(17)

in

their

proper location, f a s t e n h o u s i n g s ( 3 ) a n d ( 7 )

together with bolts (20) through cover (8).

(4) S a f e t y a n d d i r e c t i o n a l v a l v e .

(a) S a f e t y v a l v e ( 4 , f i g . 6 - 2 7 ) a n d d i r e c -

tional valve (1) can be removed from valve housing

(2) for inspection.

(b) S c r e w c e n t e r s t e m o u t o f v a l v e ( 4 ) t o

remove spring (3).

(1) I n t e r n a l a d j u s t m e n t ,

(a) When hydraulic controls are installed in

t r a n s m i s s i o n , control linkage should be adjusted to

position directional valve stem (5, fig. 6-29), safety

stem (3) and speed selector valve stem (2) properly

i n their selective housings.

shown, adjust threaded drag links in ends of valve

stems so end of first land of each valve is flush with

machined face of valve housing; the end of first

l a n d of valve stem (2) must be flush with surface

( A ) , (3) with surface (B), and (5) with surface (C).

CAUTION

(2) E x t e r n a l a d j u s t m e n t .

Valve stem (5) may be thrown with

WARNING

considerable force by spring (3) when

Do not adjust linkage with engine

threads

are

disengaged.

running.

(c) When assembling safety valve, apply

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |