|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

scoring, scratches, grooves or wear. Replace if worn

(3) Compensate for worn timing gears by

or damaged. Measure the camshaft bearing sur-

a d j u s t i n g the fuel injection pump lifters (para 5-

f a c e s using a micrometer. If any diameter is less

11).

than 1.40 inches, replace the camshaft.

( 4 ) If the backlash measurement is low, check

f o r a burr or rough spot on one of the gears a n d

(3) Inspect the camshaft bearings for wear

a n d s u r f a c e d a m a g e . R e p a i r if possible or replace

s m o o t h as required.

b e a r i n g s as required.

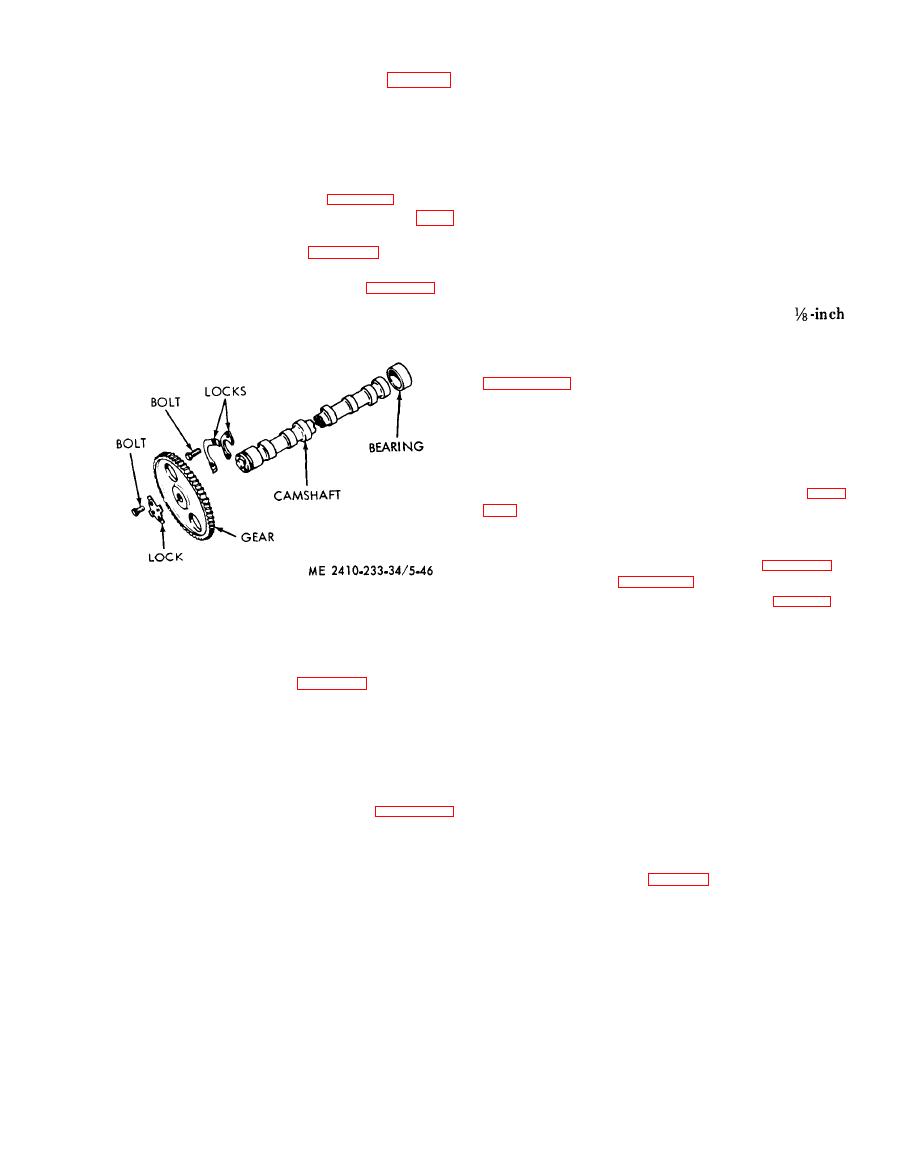

5-30. Cam shaft

(4) Inspect the camshaft gear for broken

a. Removal and Disassembly (fig. 5-46).

t e e t h , cracks, scratches, scoring and wear. Repair

( 1 ) Remove the engine from the tractor

o r replace as required.

2-8).

d. Reassembly and Installation.

( 2 ) Remove the pushrods (para 5-27) and lift

(1) Install the camshaft bearings in the

t h e valve lifters clear of the camshaft.

cylinder block. Align the oil holes in the front

( 3 ) Remove the timing gear cover (para 5-29).

b e a r i n g with the oil hole in the block. Install the

(4) Remove two bolts and the washer and pull

f r o n t and rear bearings so that there is a

the camshaft and camshaft gear from the block. Be

clearance

between

the

cylinder

block

and

the

c a r e f u l not to damage the camshaft bearings.

bearing.

(2) Install the flywheel housing, if removed

(3) Install the gear to the camshaft. Secure

w i t h the lock and four bolts.

( 4 ) Install the camshaft and camshaft gear in

the block and secure with the washers and two

bolts.

( 5 ) Check the camshaft gears backlash (para

(6) Check

the

camshaft

end

clearance

(subpara e).

( 7 ) Install the timing gear cover (para 5-29)

and the pushrods (para 5-27).

(8) Install the engine in the grader (para 2-8).

e. Checking Camshaft End Clearance.

(5) Remove four bolts and the lock and pull

(1) Push the

washer

forward

against

the

t h e gear from the camshaft.

cam shaft gear.

(6) If camshaft bearings are to be removed,

(2) Using a thickness gage, measure the

r e m o v e the flywheel housing (para 5-31) and press

distance between the washer and the end of the

t h e bearings out of the block.

c a m s h a f t bearing journal. The clearance should be

b. Cleaning.

0.004 to 0.010 inch and must not exceed 0.025

(1) Clean the camshaft thoroughly with

inch.

cleaning solvent (Fed. Spec. P-D-680). Blow out

Power

Take-Off

Drive

Gears

and

t h e oil holes with compressed air. Dry with clean,

Bearings

l i n t - f r e e cloths or with compressed air.

a. Removal.

( 2 ) Clean bearings as instructed in paragraph

(1) Remove transmission oil pump, winch

2-6.

hydraulic pump, and bulldozer hydraulic pump

c. I n s p e c t i o n

and

Repair.

(TM

5-2410-233-20).

(1) Using a magnetic particle technique,

( 2 ) Remove bolts (fig. 5-47) and remove cover

inspect the camshaft for cracks. Replace if any

f r o m flywheel housing. Remove the thrust washers

c r a c k s are detected.

from the cover assembly.

(2) Inspect the

camshaft

for

roughness,

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |