|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

c. lnstallation. Reverse removal procedure and

install the exhaust manifold on engine.

manifold for cracks, broken mounting flanges, or

other damage. Weld cracks and other minor

damage according to TM 9-237. Replace an ex-

cessively damaged exhaust manifold.

Section IV. ELECTRICAL SYSTEM

5-19. General

(13) Remove dowel pins (9) only if they

require replacement.

The tractor electrical system supplies the power to

(14) Remove screw (45). Remove four screws

start the engine and operate the lights and in-

(21), receptacle connector (22) and leads (27) and

struments. The system consists of batteries,

(28).

Remove leads only if they require

replacement.

switches, and other electrical components. Refer to

(15) Remove four screws (23), elbow (24)

and elbow spacer (26).

5-20. Generator

(16) If coil assemblies (20), (38), (39) and

(41) require replacement, remove two screws (17)

am pere type mounted on the right-front of the

securing each pole shoe (18) to housing. Remove

engine. It is fungus and corrosion resistant and is

pole shoes, windings and insulators (19).

arranged for B-type circuit with the field grounded

d. Cleaning.

inside the generator.

(1) Clean the armature and field windings of

b. Removal. Refer to TM 5-2410-233-20 for

any dirt or magnetized particles. To remove grease

the removal of the generator.

and oil, apply a light coat of cleaning solvent (Fed.

c. Disassembly.

Spec. P-D-68) with a brush. Wipe clean, then use

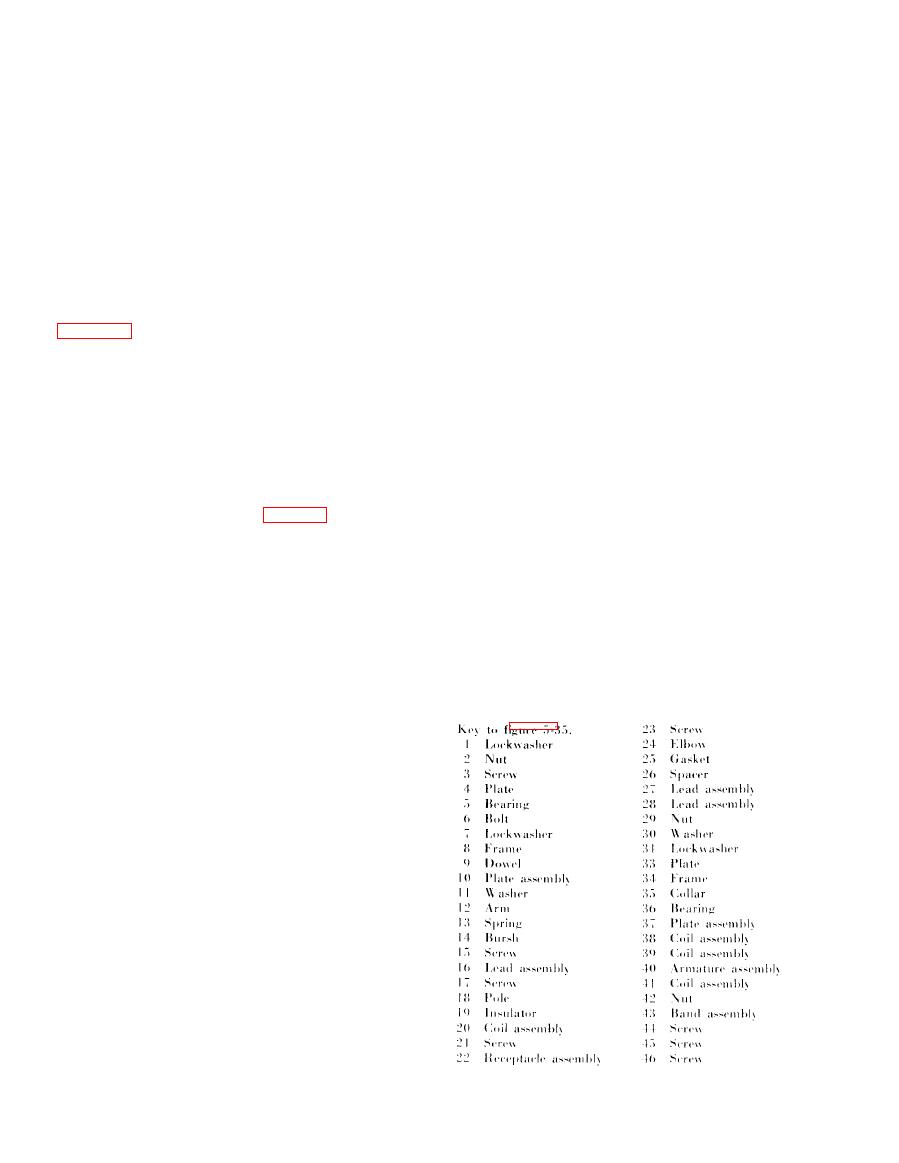

(1) Remove nut ((29), fig. 5-35) flat washer

compressed air to remove any remaining dirt film.

(30) and collar (35).

Do not use any decreasing compounds or submerge

(2) Remove screw (44), nut (42) and cover

the armature in a degreasing tank as this would

band (43).

damage the insulation.

(3) Scribe marks across end frames and

(2) Clean the commutator with 00 sandpaper

housing for use in aligning parts in reassembly.

and remove sand particles with compressed air,

(4) Remove six hex-head bolts (6) and lock-

(3) Clean the commutator end frame, drive

washers (7) securing commutator end frame (8) to

end frame, and components with cleaning solvent

housing.

(Fed. Spec. P-D-680) and dry thoroughly.

(5) Remove assembled washer screws (15)

CAUTION

and remove lead (10). Mark leads and brush

Do not soak insulators.

holders to assure correct connections are made in

reassembly.

(6) Remove assembled end frame (8) and

brush plate assembly (10).

(7) Remove six hex-head bolts (6) and lock-

washers (7) securing drive end frame (34) to

housing. Remove end frame.

(8) Remove armature (40), bearings (5) and

(30) and inner bearing retaining plate (37).

( 9 ) Remove brushes (14). Remove four

screws (46), nuts (2), lockwashers (1) and separate

brush plate assembly (10) from end frame.

(10) Remove four springs (13), electric

contact arms (12), and flat washers (11) from

brush plate assembly (10).

(11) Remove four screws (3) and remove end

frame plate (4).

(12) Remove six screws (31), lockwashers

(32) and remove retaining plate (33) from drive

end frame (34).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |