|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

compressed air to remove deposits. Do not use a

wire brush or steel blade scraper to clean

trubocharger components.

NOTE

Make sure the wheels are thoroughly cleaned. Deposits

left on these parts will affect their balance.

e. Inspection and Repair.

(1) Inspect wheel assembly and compression

wheel for cracked, bent or damaged blades.

CAUTION

Do not attempt to straighten wheel

blades.

(2) Refer to table 1-3 and inspect bearing

journals and shaft for excessive wear.

(3) Inspect seal groove walls for scoring or

scratches.

(4) Inspect bearings for wear, looseness,

corrosion and binding. Replace a defective bearing.

(5) Refer to table 1-3 and inspect housing

bore for scratches or excessive wear. Replace

housing if bearing bores are excessively scratched

or worn beyond the maximum allowable wear

limits.

(6) Inspect dirt deflector ring (14) (fig. 5-30)

for wear or other damage to seal grooves or

deflector is damaged.

(7) Inspect sleeve (18), thrust bearing (17)

and ring (19) for excessive wear or damage.

Replace parts if faces are mutilated. Replace thrust

bearing if worn beyond maximum allowable wear

limits listed in table 1-3. The small drilled oil holes

in the thrust bearing must be clean and free of

obstruction.

(8) Inspect oil deflector (16) for excessive

wear or scoring. Replace a defective oil deflector.

(9) Inspect shaft insert (12) for wear or

scoring. Replace if bore is scored or worn beyond

maximum allowable wear limits listed in table 1-3.

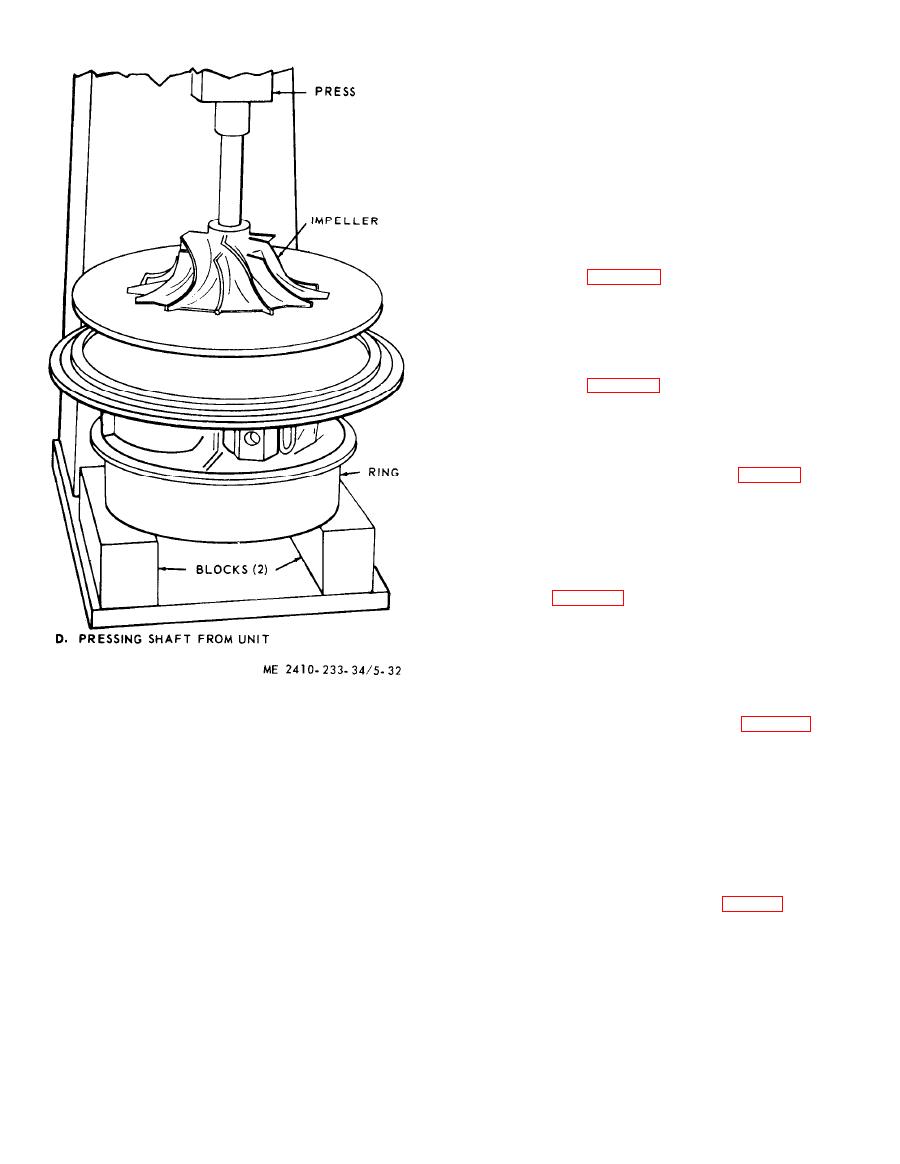

(7) Remove the unit from the press and place

(10) Inspect retaining ring (11) for proper

on bench, compressor end down.

spring tension. Replace a defective ring,

(8) Remove insert retaining ring (11) from

(11) Discard and replace all seal rings and

bearing housing (26). Install two No. 10-24

packing. Replace all defective parts.

screws in shaft insert (12) and pull insert out of

f. Reassembly. The turbocharger must be

bearing housing (26). Push out ring (14) and

assembled in accordance with the following

remove seal (15).

procedures. Measure all clearances accurately.

(9) Remove the oil deflector (16). Remove

Lubrication, unless otherwise specified, will be a

thrust bearing (17), sleeve (18), and ring (19).

clean, light oil OE10.

(10) Remove four shaft rings (20), and

(1) Clamp the turbine housing (8, fig. 5-30) in

bearing (22) and sleeve (21) from bearing housing

a vise or fixture.

(26).

(2) Place turbine wheel and shaft assembly

(11) Remove retaining ring (23) and shroud

(9) with shaft upright in housing. Place seal ring

(24) from bearing housing (26).

(25) over shaft.

(12) Remove seal (25) from shaft of wheel

(3) Install shroud (24) in bearing housing

assembly (10).

(26) and secure with retaining ring (23) with flat

d. Cleaning.

side of ring resting against plate.

(1) Wash all parts except bearings in cleaning

(4) With the compressor end of housing (26)

solvent (Fed. Spec. P-D-680) and dry thoroughly.

up, install shaft ring (20) with flat side of ring

(2 ) Use a soft brush, plastic blade scraper, or

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |