|

|||

|

|

|||

|

Page Title:

Chapter 2. DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

CHAPTER 2

DIRECT SUPPORT AND GENERAL SUPPORT

MAINTENANCE INSTRUCTIONS

Section I. REPAIR PARTS, SPECIAL TOOLS AND EQUIPMENT

The special tools required to perform direct and

Repair parts and equipment required to perform

general support maintenance on the Caterpillar

direct and general support maintenance of the D-

Model D-7F Tractor are listed in appropriate TDA

7F tractor are listed and illustrated in TM 5-2410-

of the organization performing the maintenance.

233-34P.

Section Il. TROUBLESHOOTING

2-3. General

probable causes of the

trouble. The corrective

a c t i o n recommended is described opposite the

T h i s section provides information useful in

probable cause. Refer to TM 5-2410-233-20 for

diagnosing and correcting unsatisfactory operation

initial troubleshooting. Any trouble that is beyond

or failure of the tractor and its components.

the scope of direct and general support main-

2 - 4 . Troubleshooting

tenance must be reported to depot maintenance

Malfunctions which may occur are listed in Chart

personnel.

2-1. Each malfunction stated is followed by a list of

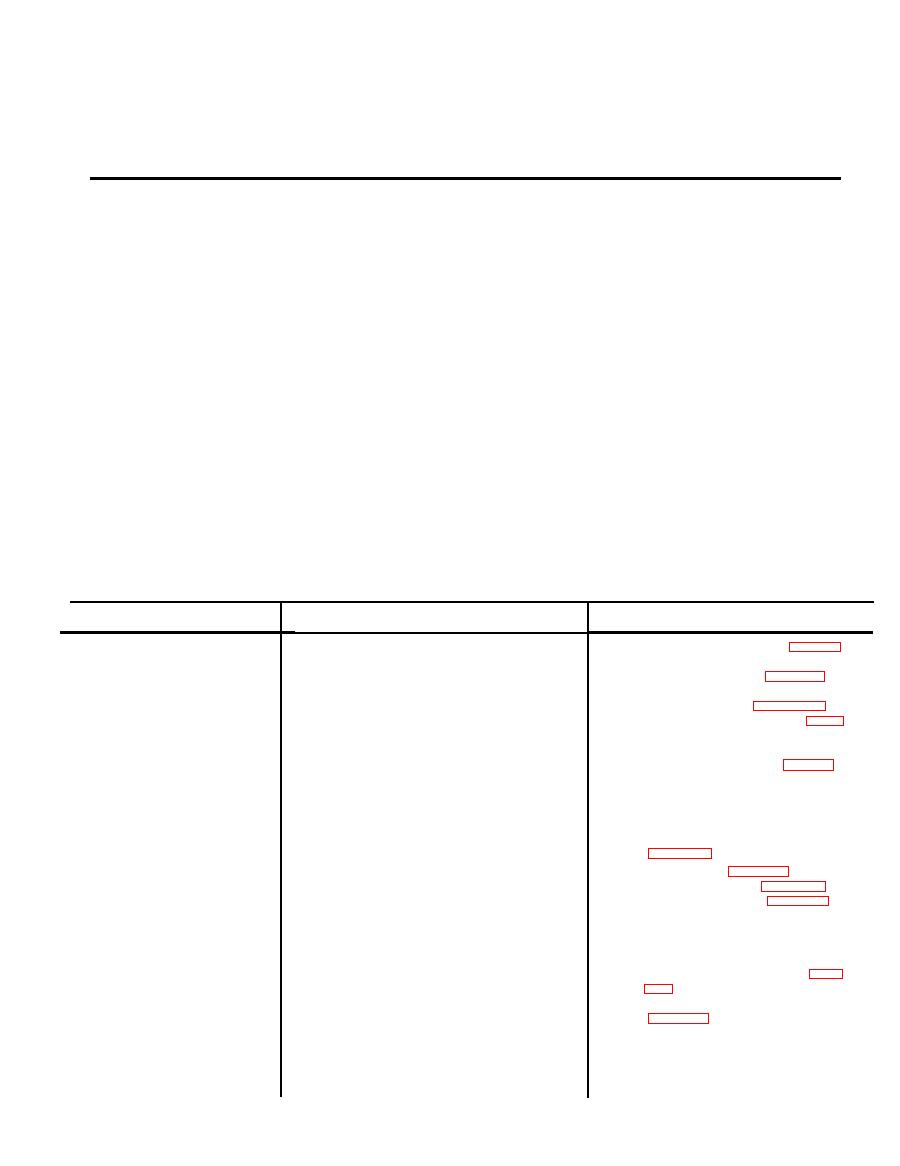

Chart 2-1. Troubleshooting

Malfunction

Corrective Action

Probable Cause

a. R e p l a c e i n j e c t o r p u m p ( p a r a 5 -

a. Worn injector pump

1. Engine fails to start

11).

b. Fuel transfer pump defective

if below 10 psi. replace fuel

transfer pump (para 5-13).

c. Slipping fuel injector pump drive

5-13), crank engine and observe

if shaft rotates. If shaft rotates,

remove the small cover (fig. 5-42)

from the front of timing gear

cover and tighten the accessory

drive gear retaining nut. If

tightening eliminates the slip-

ping, retime fuel injector pump

(para 5-11 and 5-28).

d. Engine improperly timed

d.

Retime engine (para 5-28).

a. Valves not seating properly

a.

Recondition valves (para 5-27).

2. Irregular firing of engine

b. Worm pistor rings

b.

Replace piston rings (para 5-33).

c. Defective fuel injectiong nozzle

c.

Locate misfiring cylinder by

momentarily loosening each fuel

line not on injection pump.

Replace defective fuel injection

nozzle of misfiring cyinder (para

d. R e p a c e h i g h p r e s s u r e f u e l l i n e

d. Broken or leaking high pressure

line.

Governor faliure

Check for damage or broken

3. Erratic engine speed

springs linkages, or other

governor related components.

Replace a defective governor.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |