|

|||

|

|

|||

|

Page Title:

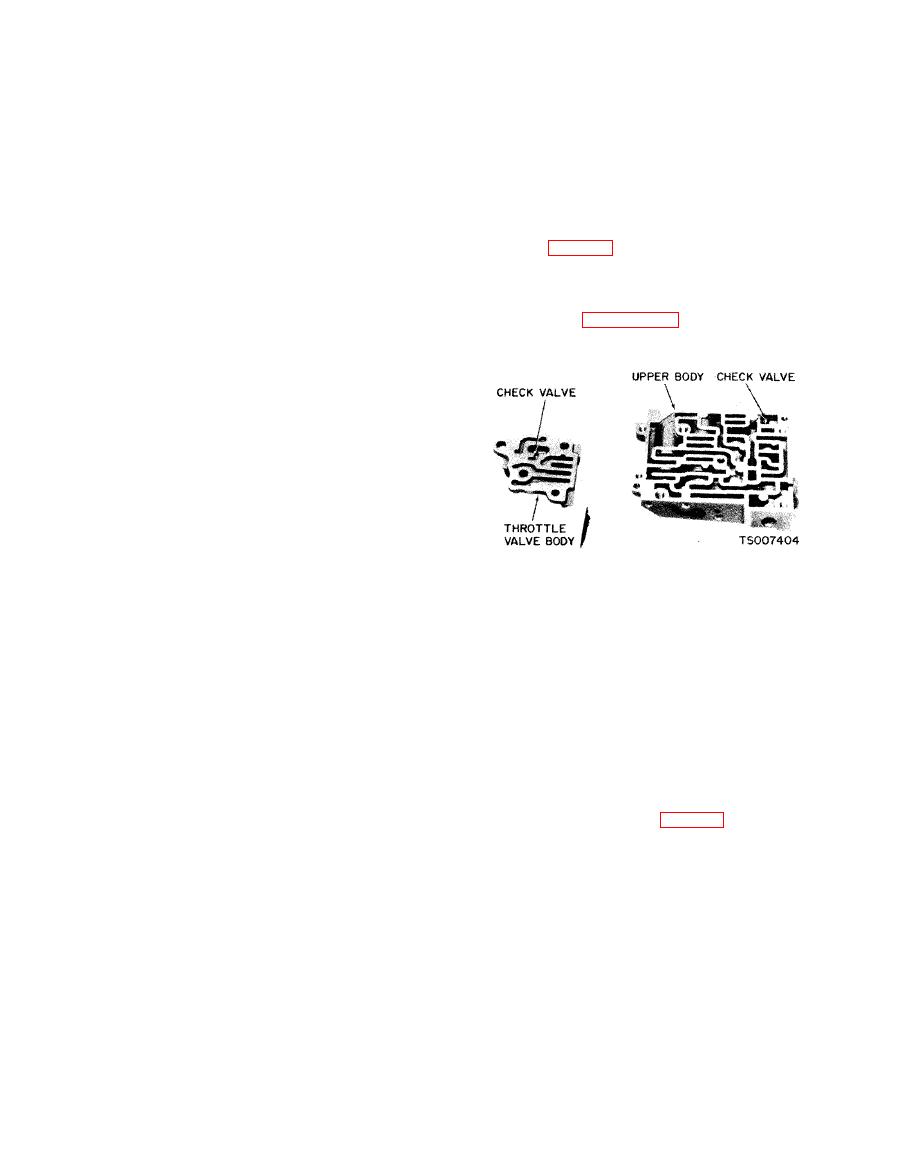

Figure 7-16. Check Valve Locations. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

all valves and plugs for free movement in their

plug, and remove the compensator valve springs.

respective bores. Valves and plugs, when dry,

Remove the compensator valve.

m u s t fall from their own weight in their

(5) Remove the throttle boost short valve

respective bores.

and sleeve. Remove the throttle boost valve

(4) Roll the manual valve on a flat surface to

spring and valve.

(6) Remove the downshift valve and spring.

check it for a bent condition.

(7) Remove the upper valve body rear plate.

d. Reassembly.

(8) Remove the compensator cut back valve.

(1) Arrange all parts in their correct

(9) Remove the lower body side plate. The

positions (fig. 7-15) Rotate the valves and plugs

plate is spring-loaded. Apply pressure to the plate

when inserting them in their bores to avoid

while removing the attaching screws.

shearing of soft body castings.

(10) Remove the 1-2 shift valve and spring.

(2) Place the check valve in the upper body

Remove the inhibitor valve and spring.

as shown in figure 7-16. Then, position the

(11) Remove the two screws attaching the

separator plate on the body.

separator plate to the cover. Remove the lower

body end plate. The end plate is spring-loaded.

Apply pressure to the plate while removing the

attaching screws.

(12) Remove the low servo lockout valve,

low servo modulator valve and spring.

(13) Remove the 2-3 delay and throttle

reducing valve sleeve, the throttle reducing valve,

spring, and the 2-3 shift delay valve. The

reducing valve sleeve is lightly staked in the valve

body bore. To remove the sleeve, use a blunt

instrument against the end of the 2-3 shift valve

and push the sleeve from its bore. Remove the 2-3

shift valve spring, spring retainer and valve.

(3) Position the lower body on the upper

(14) Remove the transition valve spring and

body, and start but do not tighten the attaching

valve.

screws.

(4) Position the cover and separator plate on

(15) Remove the plate from the valve body

the lower body. Start the four through bolts.

cover.

(5) Align the separator with the upper and

(16) Remove the check ball spring and check

lower valve body attaching bolt holes. Install and

ball. Remove the 3-2 kickdown control valve

torque the four valve body bolts to 20 -- 30

spring and valve.

in./lbs. Excessive tightening of these bolts may

(17) Remove the 1-2 shift accumulator valve

distort the valve bodies, causing valves or plugs

spring retainer from the cover. Remove the

to stick.

spring, 1-2 shift accumulator valve and 1-2 shift

(6) Install the 3-2 kickdown control valve

accumulator lockout valve.

and spring and the check ball and spring in the

(18) Remove the through bolts and screws.

cover. Install the plate (fig. 7-15).

Then, separate the bodies. Remove the separator

(7) Insert the 1-2 shift accumulator lockout

plates from the valve bodies and cover. Be careful

valve, 1-2 shift accumulator valve, and spring in

not to lose the check valves.

the cover. Install the valve spring retainer.

c. Cleaning and Inspection.

(8) Install the transition valve and spring in

(1) Clean all parts thoroughly in clean

the lower body.

solvent, and then blow them dry with moisture-

(9) Install the 2-3 shift valve, spring retainer

free compressed air.

and spring. Install the 2-3 shift delay valve and

(2) Inspect all valve and plug bores for

the spring and throttle reducing valve in the

scores. Check all fluid passages for obstructions.

sleeve. Slide the sleeve and valve into position in

Inspect the check valve for free movement. In-

the lower body. Do not restake the sleeve.

spect all mating surfaces for burrs or distortion.

(10) Install the low servo lockout valve

Inspect all plugs and valves for burrs or scores.

spring. Install the low servo modulator and low

Crocus cloth can be used to polish valves and

servo lockout valves. Install the lower body end

plugs if care is taken to avoid rounding the sharp

plate.

edges of the valves and plugs.

(3) Inspect all springs for distortion. Check

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |