|

|||

|

|

|||

|

Page Title:

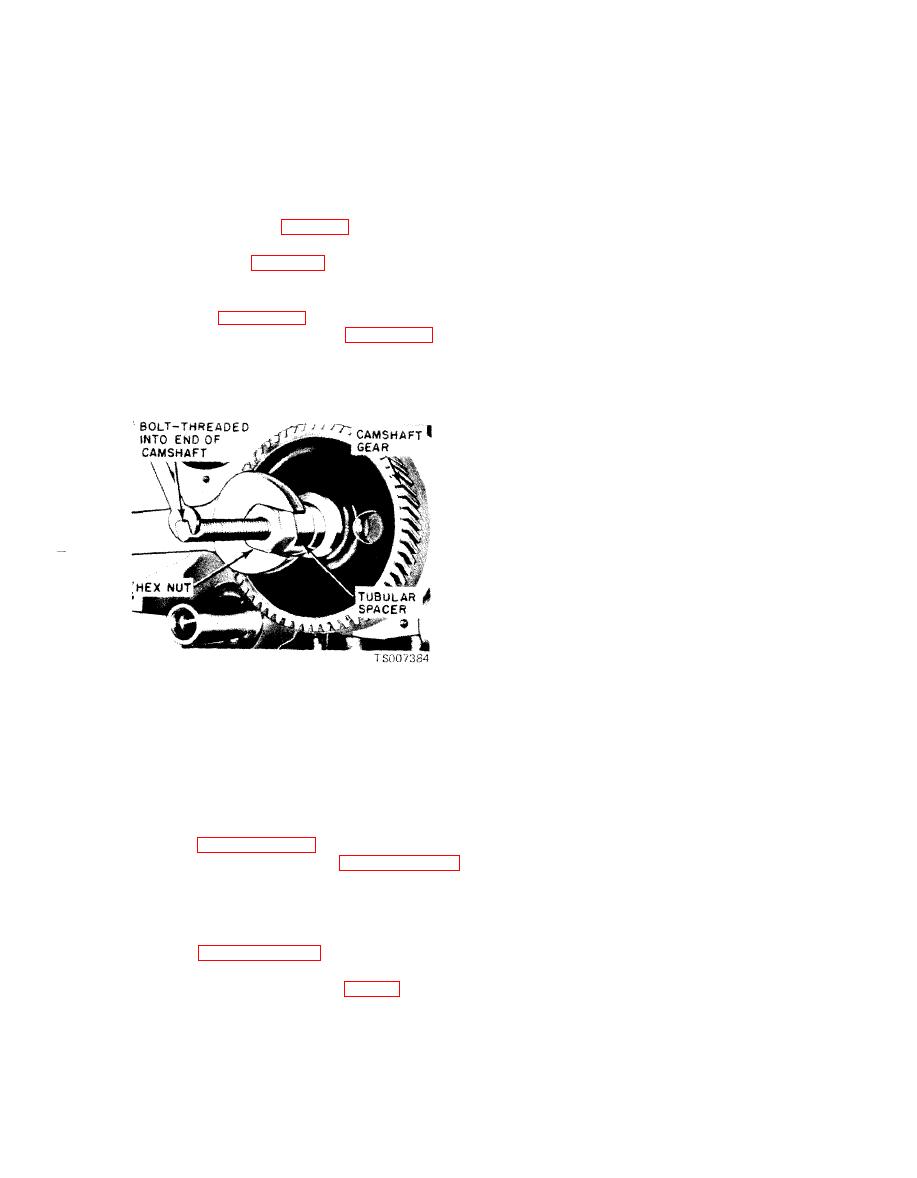

Figure 6-55. Installing Camshaft Gear. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

(9) Clean the valve pushrod cover and

b. Installation. If the camshaft end play,

c y l i n d e r block gasket surfaces. Apply oil-

timing gear backlash and/or timing gear runout

resistant sealer to one side of a new gasket and

were excessive, make the necessary corrections

place the gasket on the pushrod cover with the

before installing the camshaft.

cemented side next to the cover. Install the cover

(1) Oil the camshaft bearing journals and

and torque the bolts in sequence to specifications.

apply Lubriplate or equivalent to all the lobes.

(10) Apply Lubriplate or equivalent to the

(2) Install the camshaft, gear and thrust

valve pad on the rocker arms. Oil the valve stems

plate as an assembly, making sure that the timing

with heavy engine oil. Align the valve rocker

marks are in alignment (fig. 6-36).

arms with the valves and pushrods. Tighten the

(3) Torque the thrust plate attaching screws

rocker arm stud nuts sufficiently to hold the

to specifications (see table 6-3).

pushrods in place. Adjust the valve clearance

( 4 ) Position the camshaft gear on the

following instructions given in TM 10-3930-633-

camshaft. Align the timing marks on the timing

12.

gears as shown in figure 6-36. Install the cam-

(11) Clean the valve rocker arm cover and

shaft gear with the tool shown in figure 6-55. Be

cylinder head gasket surface. Place the new

sure the gear and spacer are tight against the

gasket in the cover making sure that the tabs of

shoulder on the camshaft.

the gasket engage the notches provided in the

cover. Install the cover and torque the screws in

sequence to specifications.

(12) Set the distributor rotor so the points are

about to open for No. 1 cylinder firing position.

Install the distributor. Check the points. If the

camshaft timing marks are still aligned (step 6

above), the points should be fully open in No. 1

cylinder firing posit ion. If the points are not open,

remove the distributor and rotate the shaft in the

proper direction. Install the distributor and hold-

down clamp.

(13) Install the distributor cap and spark

plug wires as an assembly. Connect the spark

plug wires to the plugs and the secondary high

tension wire to the coil.

Inspection

(5) Crank the engine until the timing marks

a. Cleaning.

are aligned. Do not turn the crankshaft again

(1) Clean the camshaft in a bath of solvent,

until the distributor is installed.

Federal Specification P-D-680, and wipe dry.

(6) Clean the cylinder front cover and

(2) Clean timing gears in solvent bath and

cylinder block gasket surfaces. Install a new oil

dry with compressed air.

seal in the cylinder front cover. Clean the

b. Inspection.

crankshaft damper and inspect it, following the

(1) Inspect the gear teeth for scores, nicks,

procedures in paragraph 6-30. Install the cylinder

etc. Note the condition of the teeth contact

front cover and damper following paragraph 6-36.

pattern. If the teeth are scored, replace the gears.

(7) Clean the oil pump screen. Clean the oil

(2) It is not necessary to replace the gears in

pan and the gasket surfaces of the cylinder block.

sets. Replace the camshaft gear and check the

Install the oil pump screen and inlet tube and oil

b a c k l a s h , runout, etc., to determine if the

pan, following the procedures under Oil Pan

crankshaft gear should be replaced.

Installation, paragraph 6-43.

(3) Inspect the camshaft lobes for scoring

(8) Lubricate the valve lifters with heavy

and signs o f abnormal wear. L o b e wear

engine oil and install the lifters (fig. 6-6) in the

characteristics may result in pitting in the general

same bores from which they were removed. Apply

area of the lobe toe. This pitting is not

Lubriclate or equivalent to both ends of the

detrimental to the operation of the camshaft;

pushrods and install the pushrods in the same

therefore, the camshaft should not be replaced

sequence that they were removed. Be sure the

pushrods were seated in the valve lifter sockets.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |