|

|||

|

|

|||

|

Page Title:

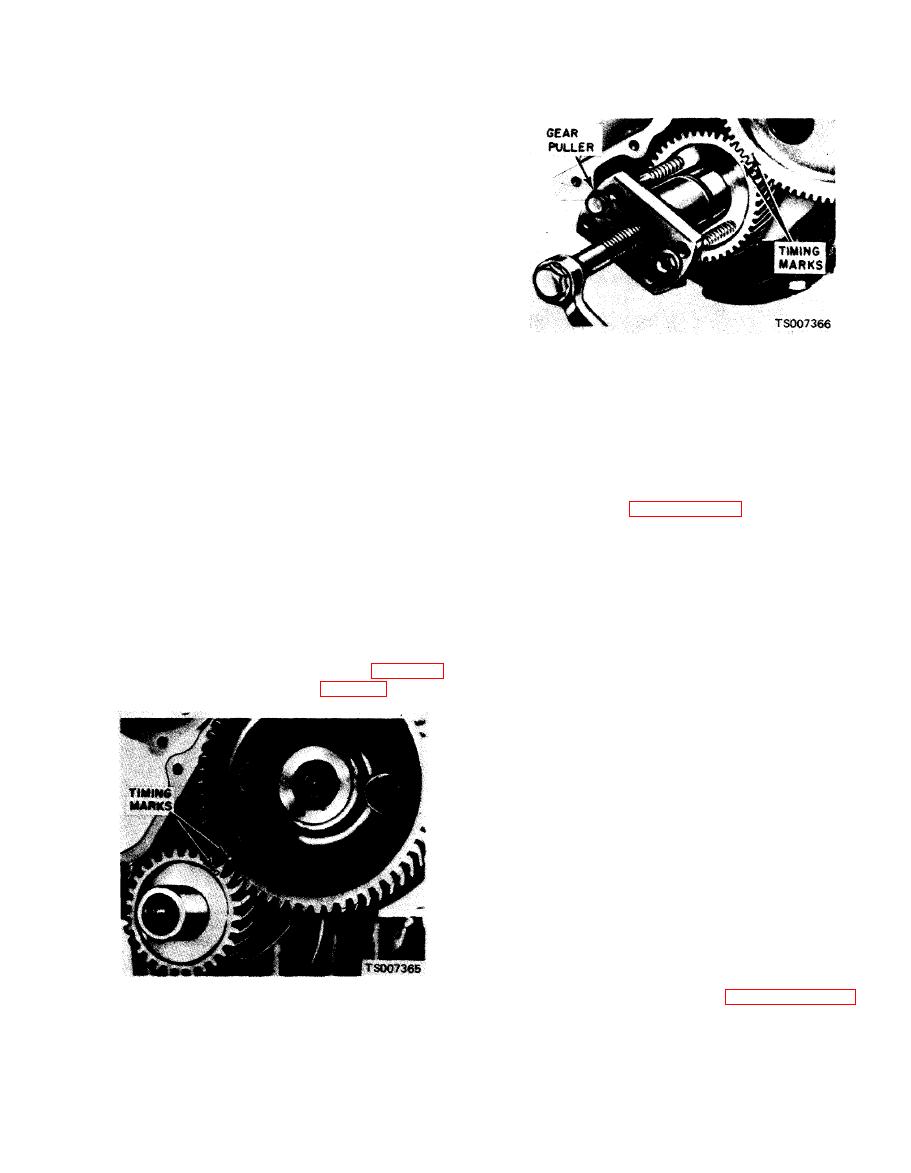

Figure 6-37. Removing Crankshaft Gear. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

(4) Remove the cylinder front cover and

gasket.

(5) Remove the flywheel and engine rear

cover plate.

(6) Turn the engine on the work stand so that

the bottom of the engine is up. Remove the oil

pan, gaskets and seals. Remove the oil pump and

inlet tube assembly. Discard the oil pump gasket.

(7) Use an awl to punch two holes in the

crankshaft rear oil seal. Punch the holes on op-

posite sides of the crankshaft and just above the

bearing cap to cylinder block split line. Install a

sheet metal screw in each hole. Use two large

screwdrivers or small pry bars and pry against

both screws at the same time to remove the

crankshaft rear oil seal. It may be necessary to

place small blocks of wood against the cylinder

(10) Remove the main bearing caps and

block to provide a fulcrum point for the pry bars.

bearings.

Use caution throughout this procedure to avoid

(11) Carefully lift the crankshaft out of the

scratching or otherwise damaging the crankshaft

cylinder block so that the thrust bearing surfaces

oil seal surface.

are not damaged. Handle the crankshaft with care

(8) Make sure all bearing caps (main and

to avoid possible fracture or damage to the

connecting rod) are marked so that they can be

finished surfaces.

installed in their original locations. Turn the

(12) Refer to paragraph 6-30 for the cleaning

crankshaft until the connecting rod from which

and inspection procedures. Be sure the oil seal

the cap is being removed is at the bottom of the

surfaces on the crankshaft and crankshaft damper

stroke. Remove the connecting rod cap and

are properly cleaned.

bearings. Push the connecting rod and piston

b. Installation.

assembly up in the cylinder. Do not turn the

(1) Remove the main bearing inserts from the

crankshaft completely around as the rod bolts

block and bearing caps.

may damage the crankpin journals. Repeat this

(2) Remove the bearing inserts from the

procedure and remove all connecting rod caps.

connecting rod caps.

(3) Clean the crankshaft rear oil seal recess in

(9) Align the timing marks (fig. 6-36).

the cylinder block and rear main bearing cap.

Remove the crankshaft gear (fig. 6-37).

(4) If the crankshaft main bearing journals

have been refinished to a definite undersize,

install the correct undersize bearings. Be sure the

bearing inserts and bearing bores are clean,

Foreign material under the inserts will distort the

bearing and cause a failure.

(5) Place the upper main bearing inserts in

position in the bore with the tang fitting in the

slot provided. Be sure the oil holes in the bearing

inserts are aligned with the oil holes in the

cylinder block transverse webs.

(6) Install the lower main bearing inserts in

the bearing caps with the tang fitted in the slot.

(7) Carefully lower the crankshaft into place.

Be careful not to damage the bearing surfaces.

(8) Check the clearance of each main bearing

following procedures given in paragraph 6-33

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |