|

|||

|

|

|||

|

Page Title:

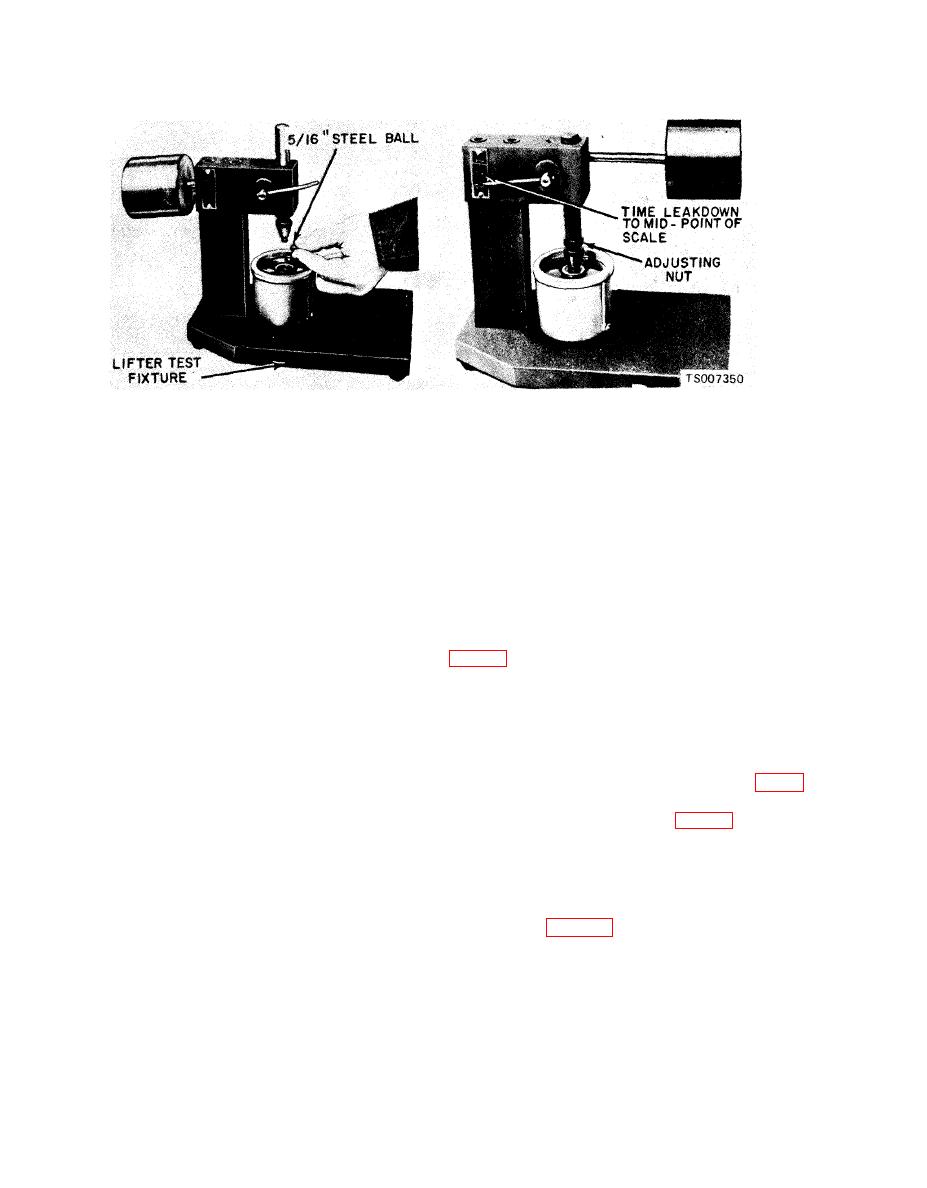

Figure 6-21. Testing Hydraulic Lifter, |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

(3) Place the valve lifter in the tester, with

the plunger facing upward. Pour hydraulic tester

a. General. After refacing valve seats and

fluid into the cup to a level that will cover the

checking all valve train parts as outlined in

valve lifter assembly. The fluid can be purchased

previous paragraphs, install valves as outlined

from the manufacturer of the tester. Do not use

below. Lubricate valve guides and valve stems

kerosene, for it will not provide an accurate test.

with heavy engine oil. Apply Lubriplate or

(4) Place a 5/16 inch steel ball in the plunger

equivalent compound to the tips of the valve

cup.

stems.

b. Installation.

(5) Adjust the length of the ram so that the

(1) Install each valve in the valve guide from

pointer is 1/16 inch below the starting mark when

which it was removed or to which it was fitted.

the ram contacts the valve lifter plunger to

(2) Oil and install a new intake valve oil seal

facilitate timing as the pointer passes the start

timing mark. Use the center mark on the pointer

the exhaust valves at this time.

scale as the stop timing instead of the original

(3) Install the valve spring over the valve. Be

stop timing mark at the top of the scale.

sure the closed coil end is placed against the

(6) Work the valve lifter plunger up and

cylinder head.

down until the lifter fills with fluid and all traces

(4) Position the spring retainer on all valve

of air bubbles have disappeared.

springs. Make sure that a positive rotating

(7) Allow the ram and weight to force the

retainer is used on all of the exhaust valves (fig. 6-

valve lifter plunger downward. Measure the exact

9).

time it takes for the pointer to travel from the

(5) Compress the spring (fig. 6-8). Apply

start timing to the stop timing marks on the

engine oil to the O-ring type seal, then install it on

tester.

(8) A valve lifter that is satisfactory must

the exhaust valve. Install the retainer locks.

have a leak-down rate (time in seconds) within 5

(6) Measure the assembled height of the

valve spring from the surface of the cylinder head

to 50 seconds at 1/16 inch plunger travel.

(9) If the valve lifter is not within

spring pad to the underside of the spring retainer

specifications, replace it with a new lifter. It is not

with dividers (fig. 6-22).

necessary to test a new lifter before installing it in

the engine.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |