|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-633-34

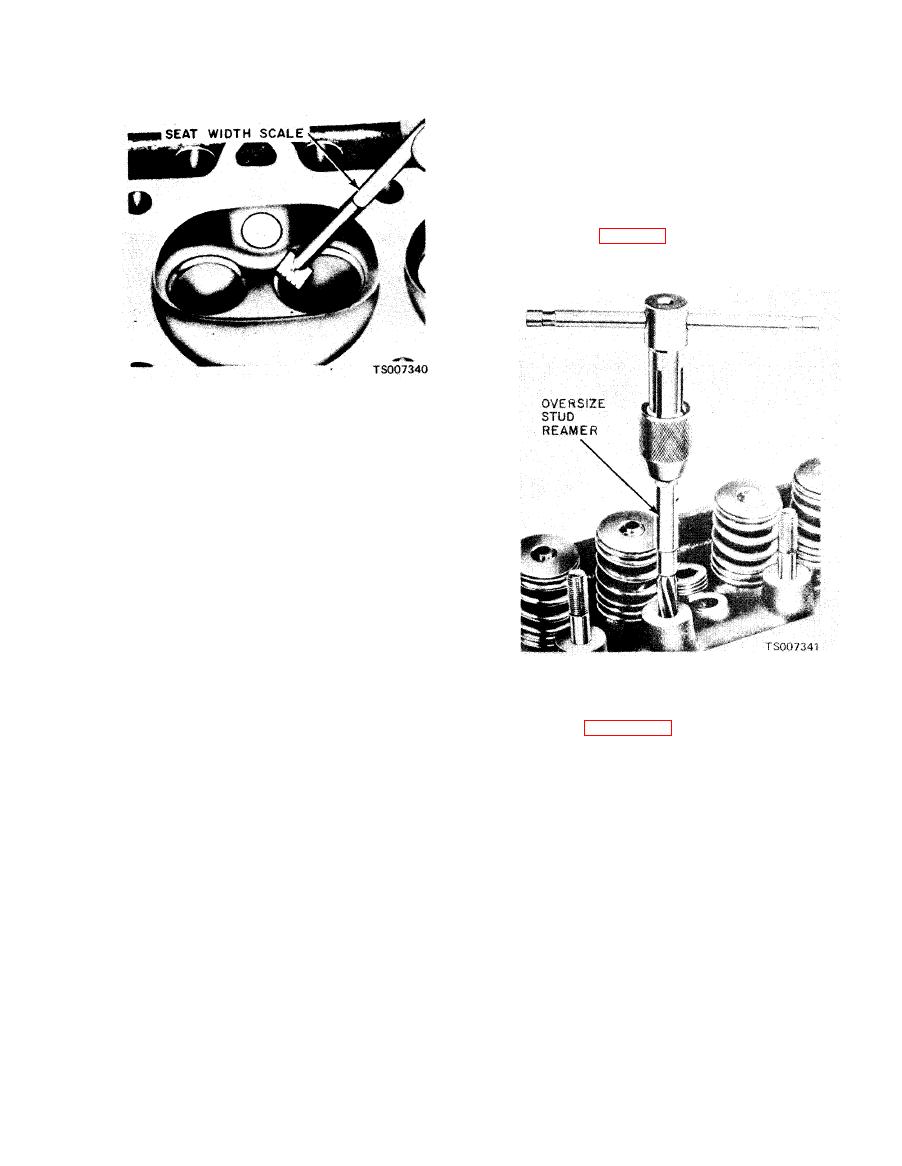

(2) When going from a standard size rocker

arm stud to an 0.010 or 0.015 inch oversize stud,

always use the 0.006 inch oversize reamer before

finish reaming with the 0.010 or 0.015 inch

oversize reamer.

(3) If a loose rocker arm stud is being

replaced, ream the stud bore using the proper

reamer (or reamers in sequence) for the selected

oversize stud (fig. 6-12). Make sure the metal

particles do not enter the valve area.

(6) Check the breakaway torque of all rocker

arm studs. 4.5 to 15 ft/lbs should be required

(counterclockwise) to break the stud away. If

breakaway torque is less than this, replace the

stud with an oversize stud.

a. Rocker Arm Stud Replacement. R o c k e r

arm studs that are broken or have damaged

threads may be replaced with standard studs.

Loose studs may be replaced with 0.006, 0.010, or

0.015 inch oversize studs, which are available for

service (TM 10-3930-633-34P). Oversize studs

may be identified by measuring the stud diameter

at a point 1-1/8 inches from the pilot end of the

stud. The stud diameters are:

(4) Install new studs with a stud driver tool

0.006 oversize . . . . . . . . . . . . . . . . . . . . . ..0.3774-0.3781

as shown in figure 6-13. Exercise care to set new

0.010 oversize . . . . . . . . . . . . . . . . . . . . ...0.3814-0.3821

0.015 oversize . . . . . . . . . . . . . . . . . . . ...0.3864-0.3871

stud at same height as adjacent studs not being

replaced.

b. Replacement Procedure.

(1) If the rocker arm stud was broken off

flush with the stud boss, use an easy-out to

remove the broken stud following the instructions

of the tool manufacturer.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |