|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-633-34

removal and replacement instructions for those

assemblies replaceable at organizational levels.

Also observe the following special precautions.

a. Before attempting removal of any electrical

component, make certain that the system is not

energized. Disconnect battery ground strap.

b. Insure that adequate clearance is available

for removal of the component. Disassemble the

truck to the extent necessary to provide adequate

working clearance.

c. Use a chain hoist, jack or other aid when

lifting the heavier components. The lifting device

should be positioned and attached to the com-

ponent to remove all strain from the mounting

hardware before the last of the hardware is

removed.

d. To facilitate reassembly and installation,

apply identifying tags to mating ends of electric

or hydraulic lines as they are disconnected.

Identify parts of similar configuration to insure

correct reassembly.

e. To prevent moisture and foreign matter

(10) Disconnect the engine wiring harness at

from entering open housings, lines, and other

the ignition coil, coolant temperature sending

openings, apply protective covers as soon as

unit, oil pressure sending unit, and vacuum

practicable after disassembly.

switch.

(11) Loosen and remove the alternator

2-24. Engine

mounting bolts, and position alternator (with

a. Removal.

w i r i n g attached) out of the way of engine

(1) Remove the two screws attaching the

removal.

hood to the hinge brackets and remove the hood.

(12) Raise the vehicle, using lifting eyes on

(2) Drain the cooling system and the engine

the frame, and block securely under the frame for

crankcase (refer to TM 10-3930-633-12).

support.

(3) Disconnect battery cable, and remove

(13) Remove the starter (see TM 10-3930-

ground strap at engine connection point.

633- 12) and the automatic transmission filler tube

(4) Remove fan, fan belts, water pump

bracket.

pulley and upper and lower radiator hoses (see

(14) From underneath the vehicle, remove

TM 10-3930-633-12).

the converter housing access cover.

(5) Remove radiator (see TM 10-3930-633-

(15) Remove the nuts which attach the

12).

converter to the engine flywheel. Use of a wrench

(6) Disconnect the accelerator and choke

on the crankshaft pulley attaching bolt will enable

cables from carburetor and anchor brackets on

the crankshaft to be turned until all nuts are

engine (refer to TM 10-3930-633-12). Disconnect

removed.

hose at fuel pump.

(16) Block or brace the converter so that it

(7) Remove air cleaner ductwork from

will remain in the housing as the engine is

carburetor (see TM 10-3930-633-12).

removed.

(8) Disconnect exhaust pipe from manifold

(17) Refer to figure 2-2 and remove the front

-

(see

TM

10-3930-633-12).

support frame bolt and nut. When engine is

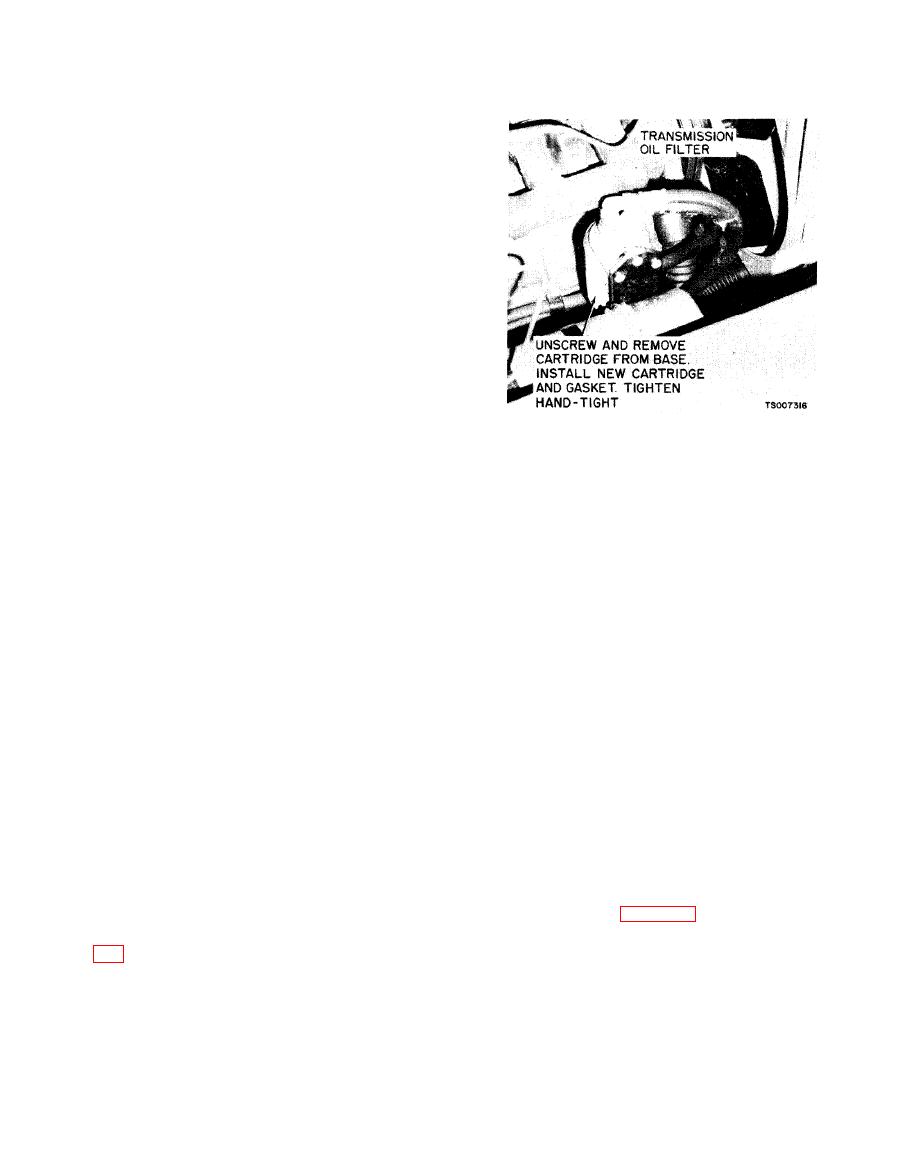

(9) Remove transmission oil filter (see figure

removed, insulators and washers m a y b e

removed.

of the way of engine removal. Remove clips from

transmission oil lines.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |