|

|||

|

|

|||

|

Page Title:

Air Cleaner Service |

|

||

| ||||||||||

|

|

TM 10-3930-633-12

(3) Install filter element making sure wing

nut is tight.

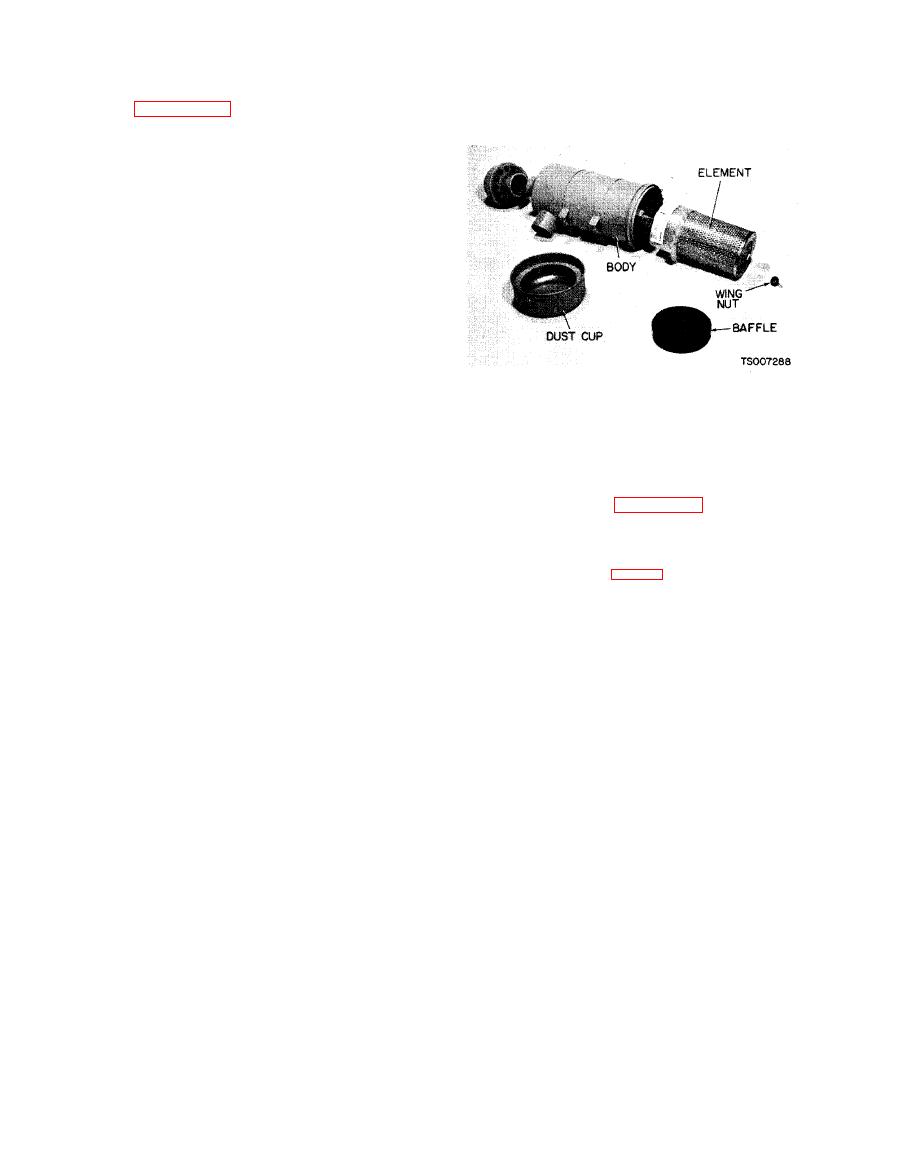

Refer to figure 4-27, showing parts of the air

(4) Replace baffle.

cleaner assembly, and service the air cleaner as

follows:

a. Dust Cup. Empty and clean dust cup every

8 operating hours or more often under extremely

dusty conditions. Dust should not be allowed to

build up in cup. Remove foreign material such as

leaves from around filter and tighten wing nut if

necessary. Replace baffle and securely replace cup

on air cleaner body.

b. Filter Element Removal. Proper servicing

means cleaning unit thoroughly and maintaining

airtight connections between the air cleaner and

intake manifold so that all air entering the engine

is filtered. Remove the filter element for cleaning

as follows:

(1) Remove cover.

(2) Lift out baffle.

If parts of the air cleaner body or system duct-

(3) Empty dust from cup.

work become damaged or deteriorated to the

(4) Remove filter element. Clean thoroughly

point that they will not form an airtight seal

by using one of the following methods.

against entry of unfiltered air, these parts must

c. Cleaning a Dusty Element. Use compressed,

be replaced. Refer to figure 4-28 and remove the

dry filtered air directing this up and down pleats

parts to be replaced as shown in the illustration.

on the clean side of the element.

When installing new parts, maintain the parts

CAUTION

relationship depicted in the illustration.

Air pressure must not exceed 100 PSI.

KEY to fig. 4-28:

Maintain a reasonable distance between

1. Air cleaner assembly

nozzle and element. Direct air through

2. Clamp

element (opposite to direction of arrows

3. cup

cast on end of element). Do not damage

4. Baffle

5. Wing nut

fins or se sling surfaces or rupture

6. Washer

element nor allow dust to deposit on

7. Element and gasket

clean air side.

8. Screw

d. Cleaning an Oily or Sooty Element. For best

9. Nut

results, use small amount of cool tap water with

10. Washer

11. Lockwasher

non-sudsing household detergent then add to

12. Clamp

w a r m (70 0 - 100 F, 21 C - 38 C) water.

13, Clamp

The warmer the solution the better the cleaning.

14. Hose

S o a k for approximately 15 minutes. Rinse

15. Nut

16. Screw

element thoroughly with clean water from hose

17. Clamp

(maximum pressure 40 PSI). Air dry completely

18. Elbow

before installing.

19. Clamp

e. Element Installation. After air cleaner has

20. Tube

21. Wing nut

dried, (a fan or air draft may be used, but do not

22. Washer

heat element to hasten drying) inspect element for

23. Adapter

damage by placing a bright light inside element.

24. Clamp

Thin spots, pin holes or the slightest rupture will

25. Adapter

render the element unfit for further use.

26. Restriction indicator

27. Elbow

(1) Clean cover, baffle and inside of filter

28. Nipple

body with a clean lint free cloth.

29. Coupling

(2) Check air cleaner hose connections for an

30. Adapter

airtight fit.

31. Hose

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |