|

|||

|

|

|||

|

Page Title:

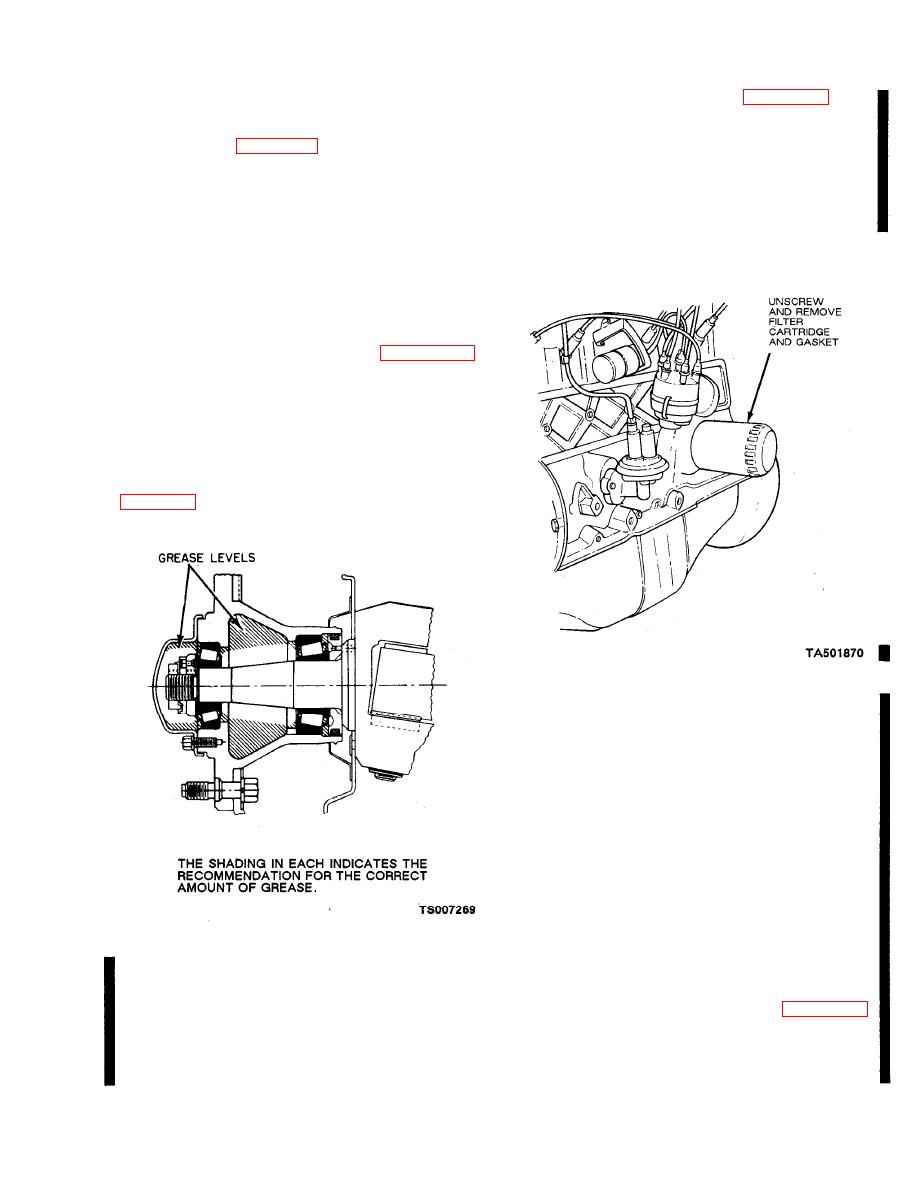

Figure 4-1. Repacking Wheel Hubs and Bearings |

|

||

| ||||||||||

|

|

TM 10-3930-633-12

(2) When removing front wheels, make cer-

tain that all air pressure is relieved, then proceed to

unscrew and remove engine oil filter cartridge.

remove the wheel by removing ONLY the inner set of

Discard old cartridge and gasket. Wipe off the base

nuts as shown in figure 4-42, Do not disturb the nuts

of the filter adapter with a clean cloth. Coat the new

on the larger bolt circle (nearer the rim).

filter gasket (furnished with filter) with clean engine

oil, and thread the cartridge up on the adapter until

WARNING

the gasket contacts the base, then tighten turn

N e v e r remove front wheels and tires

further.

w i t h o u t first completely deflating the

t i r e . Remove the valve core to make

certain that all pressure is exhausted.

D e f l a t i n g prior to removal is recom-

mended for rear tires also.

b. Lubrication. Every 1000 hours, remove

wheels, grease caps, rear axle shafts and brake drums

to expose wheel bearings refer to figure 4-42.

Thoroughly clean out bearings and recesses in brake

drums to remove all traces of old grease. Bearing

cones may be rinsed in Solvent, Federal Specification

P-D-680, and allowed to air dry. Do not spin bearings

dry with compressed air. Repack bearing cones and

hub recesses with the proper grease as specified in

the Lubrication Order LO 10-3930-633-12. Refer to

Figure 4-1.1. Engine Oil Filter

filler cap and pour 5 quarts of oil of the

recommended weight (see lubrication order) in the

rocker arm cover hole. Start the engine and check

for leakage at the filter cartridge flange; tighten

cartridge if leakage occurs. Check oil level on the

dipstick, and add sufficient oil to bring level to FULL

mark. Replace filler cap.

4-13.2. Transmission Oil Change

a. Transmission Drain.

(1) Place a drain pan under the transmission oil

pan.

(2) Starting at the rear of the pan, working to-

ward the front, loosen the attaching bolts and allow

the fluid to drain from the pan.

4-13.1. Engine Crankcase Oil and Filter Change

(3) After most of the fluid has drained, remove

a. Oil Drain. Engine crankcase oil should be

the remainder of the attaching bolts. Unscrew and

drained while hot, preferably immediately after

remove transmission oil filter shown in figure 4-1.2.

running. Remove the drain plug in the oil pan and

(4) Remove the pan, then remove the fluid fil-

allow pan to drain completely. Make certain that

ter and clip from the transmission. Clean the inside

tractor is on a level surface, so that pan will drain

of the pan. Remove all gasket material from the pan

and pan mounting face on the transmission case.

properly.

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |