|

|||

|

|

|||

|

Page Title:

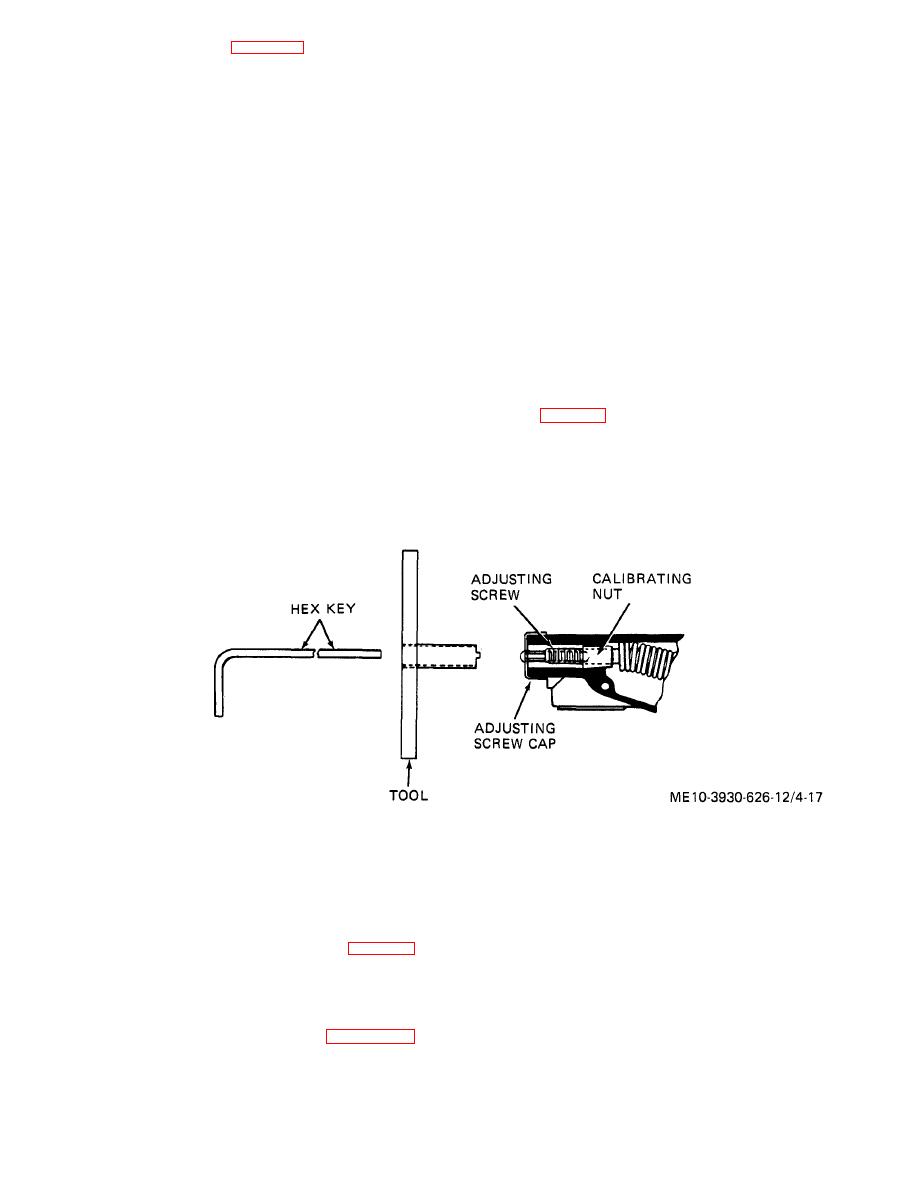

Figure 4-17. Governor adjustment. |

|

||

| ||||||||||

|

|

When installing support (13) and pad (12), force

KEY to figure 4-16:

1. Screw

support upward so that pad is snug against tank;

2. Nut

then, tighten nuts (15).

3. Lock washer

4. Fuel sender

4-39. Governor

5. Gasket

a. General.

6. Strainer

(1) Leakage at manifold, carburetor or in-

7. Filler

t e r c o n n e c t i n g gaskets must be corrected before

8. Mounting clamp

9. Fuel tank

governor can be properly adjusted,

10. Nut

(2) Thoroughly clean governor prior to

11. Screw

making

In many cases,

any

adjustments.

12. Pad

satisfactory operation can be restored by cleaning

13. Tank support

carbon and gum deposits from governor.

14. Screw

15. Nut

(3) Start and run engine until normal

16. Shutoff valve

operating temperature is reached before making

17. Fuel tank tube

adjustments.

18. Grommet

b. Speed Adjustment.

19. Drain plug

20. Screw

21, Lock washer

( 2 ) Start and run engine at full throttle.

Tachometer should indicate 2450 rpm.

b. Cleaning.

(3) To adjust for higher speed, turn adjusting

(1) Install drain plug (19) and shut-off valve

screw cap (fig. 4-17) counterclockwise, To adjust

(16). Close shut-off valve and put one gallon SD in

for lower speed, turn adjusting screw cap clockwise.

tank and slosh it around. Pour out SD quickly

O n e complete turn of adjusting screw cap will

through fill pipe, to carry out sediment.

change engine speed approximately 300 rpm.

(2) Air dry tank interior,

c. Installation. Reverse procedure in a a b o v e .

( 6 ) Engage adjustment screw with an ap-

c. Surge Adjustment.

propriate hex key,

(1) Attach tachometer to engine.

(7) Hold adjustment screw stationary with hex

(2) Start and run engine at full throttle.

(3) Remove adjusting screw cap (fig. 4-17).

time until surge is minimized or eliminated.

(4) Fabricate tool from a short piece of metal

(8) Readjust speed if necessary.

tubing. Tubing inside diameter must exceed ad-

d. Slow action adjustment. If governor does not

justing screw outside diameter and end must be cut

cut in promptly at maximum speed or does not cut

with two tangs to engage slots in calibration nut.

out promptly at governed speed when load is ap-

Handle may be added as shown in figure 4-17 if

plied, adjust for surge (subpara. c above) except

desired.

turn calibration nut counterclockwise.

(5) Engage slot in calibration nut with tool.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |